Five elements that affect the quality of insulated glass

Brenda

www.sggglassmanufactuer.com

2017-07-31 17:34:19

Nowadays, we’ve paid more attention to the energy saving of building and the quality of insulating glass has been put on the agenda. There are five elements that impact the quality of insulated glass.

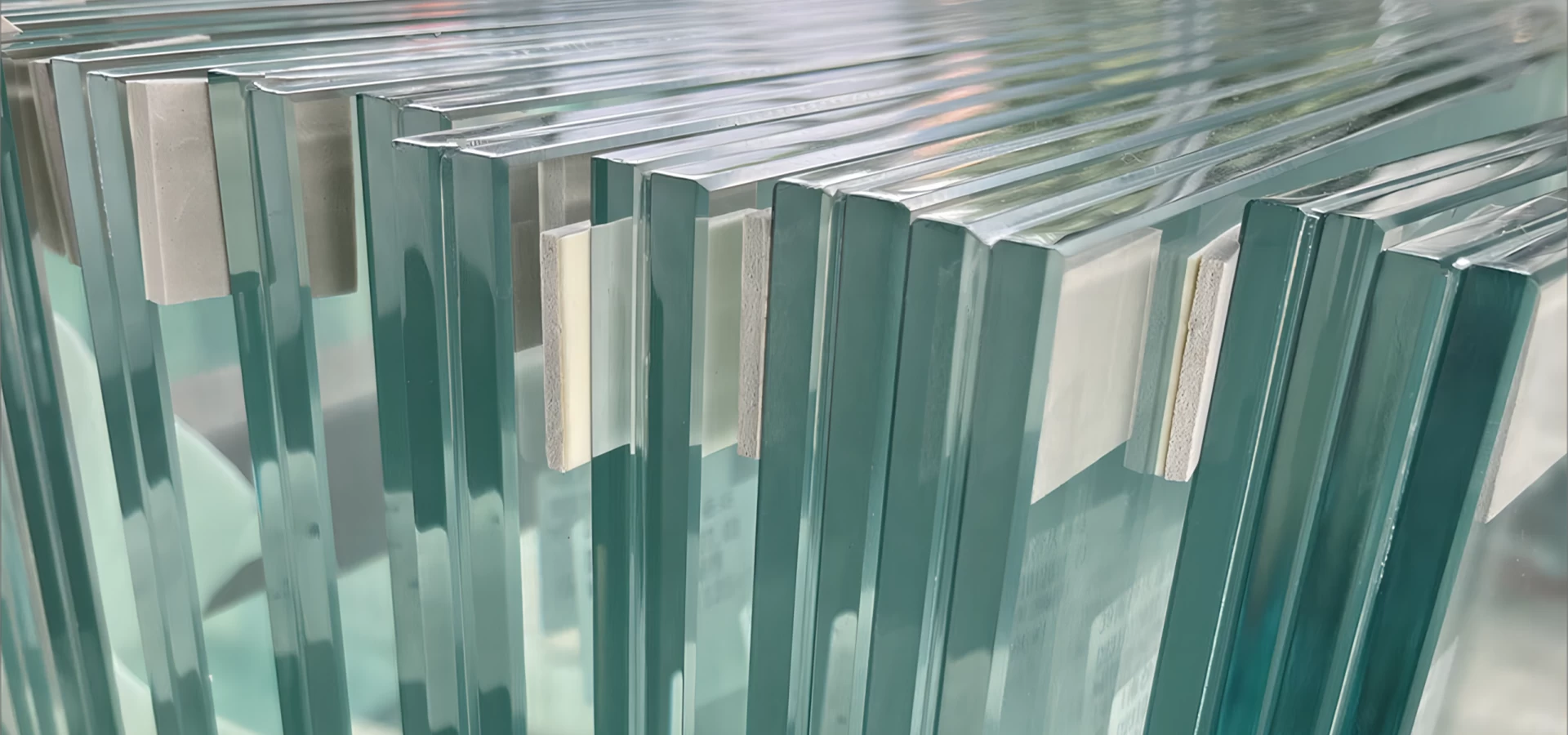

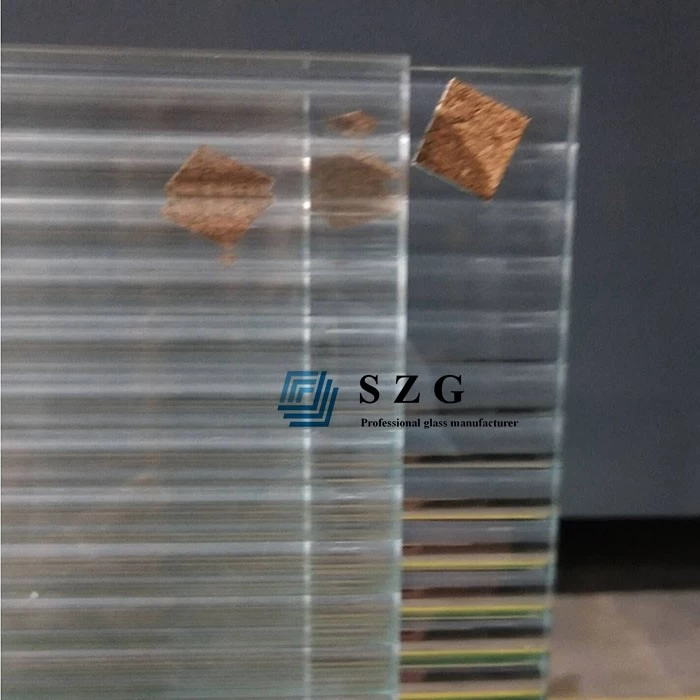

First, the selection of the original float glass.

The original float glass for insulated production can be clear float glass, tinted float glass, reflective glass, tempered glass, laminated glass, etc. These glass must pass the test successfully before being used. To check whether the color is difference before cutting. Cut the glass strictly according to the drawing, must avoid scratches, bubbles, etc.

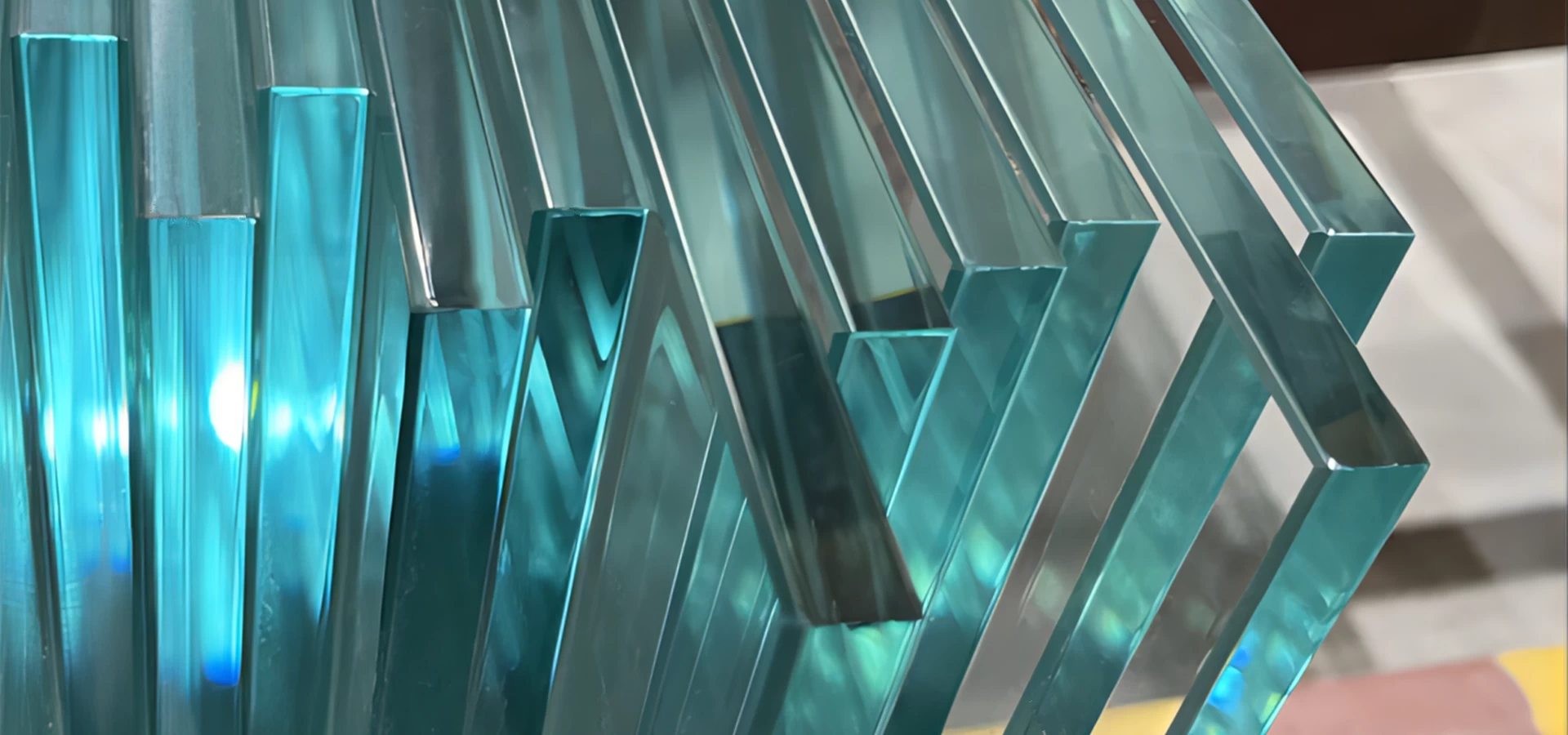

Second, selection of aluminum bar and angle.

The thickness of aluminum bar should be between 0.3-0.35mm and should be uniform with uniform distribution of ventilation holes. Aluminum bar to be anodized or via decontamination treatment to be bent, it must be with very good quality. The size of insert should be selected and its surface should be clean.

Third, the use of desiccant.

There are mainly three types of desiccant that we use in insulated glass. The first type has better ability to absorb volatiles; the inert gas adsorption quantity of second one is the lowest; the third one is ordinary molecular sieve. Users should choose the appropriate molecular sieve according to their own needs. Meanwhile, molecular sieve should have the appropriate particle size (1-1.5mm) and hardness. In addition, the environment of molecular sieve used should be dry, The filling molecules should be used within 1.5 hours to ensure that the quality of insulating glass.

Fourth, selection of sealant

1. Butyl rubber is a hot melt, with a very low water vapor transmission rate (the lowest in the insulating glass gel) and a high viscosity. It is the most effective water vapor barrier block between aluminium profiles and glass. But it needs special machine heating, pressing, extrusion coating on both sides of the aluminum bar.

2. Polysulfone is the largest amount of insulating glass sealant, polysulfide has a good resistance to oil, solvent resistance and sealing. It can be hand painted. We should choose the polysulfide that two components with color difference, valid for more than six months, anti-ultraviolet ability, good liquidity and curing flexibility.

3. Adit silicon rubber has structural, aging resistance and UV resistance, but its weakness is the high water vapor transmission rate. Thus, it’s used in the strong light, poor environment, such as glass curtain wall, etc., but we must use the butyl rubber as the first seal.

Fifth, the use of composite sealing tape

Composite sealant is a set of hollow glass raw materials, it has many advantage such as the simple operation process, less waste of raw materials, less personnel, management low costs, the operating environment is good. But the disadvantage is the moisture absorption of the tape, there must be special equipment. We should consider the surface smooth, aluminum quality, glue content, moderate viscosity, etc. when we choose the composite sealing tape

If you are interested in more information about glass, welcome to visit our website: www.sggglassmanufactuer.com

First, the selection of the original float glass.

The original float glass for insulated production can be clear float glass, tinted float glass, reflective glass, tempered glass, laminated glass, etc. These glass must pass the test successfully before being used. To check whether the color is difference before cutting. Cut the glass strictly according to the drawing, must avoid scratches, bubbles, etc.

Second, selection of aluminum bar and angle.

The thickness of aluminum bar should be between 0.3-0.35mm and should be uniform with uniform distribution of ventilation holes. Aluminum bar to be anodized or via decontamination treatment to be bent, it must be with very good quality. The size of insert should be selected and its surface should be clean.

Third, the use of desiccant.

There are mainly three types of desiccant that we use in insulated glass. The first type has better ability to absorb volatiles; the inert gas adsorption quantity of second one is the lowest; the third one is ordinary molecular sieve. Users should choose the appropriate molecular sieve according to their own needs. Meanwhile, molecular sieve should have the appropriate particle size (1-1.5mm) and hardness. In addition, the environment of molecular sieve used should be dry, The filling molecules should be used within 1.5 hours to ensure that the quality of insulating glass.

Fourth, selection of sealant

1. Butyl rubber is a hot melt, with a very low water vapor transmission rate (the lowest in the insulating glass gel) and a high viscosity. It is the most effective water vapor barrier block between aluminium profiles and glass. But it needs special machine heating, pressing, extrusion coating on both sides of the aluminum bar.

2. Polysulfone is the largest amount of insulating glass sealant, polysulfide has a good resistance to oil, solvent resistance and sealing. It can be hand painted. We should choose the polysulfide that two components with color difference, valid for more than six months, anti-ultraviolet ability, good liquidity and curing flexibility.

3. Adit silicon rubber has structural, aging resistance and UV resistance, but its weakness is the high water vapor transmission rate. Thus, it’s used in the strong light, poor environment, such as glass curtain wall, etc., but we must use the butyl rubber as the first seal.

Fifth, the use of composite sealing tape

Composite sealant is a set of hollow glass raw materials, it has many advantage such as the simple operation process, less waste of raw materials, less personnel, management low costs, the operating environment is good. But the disadvantage is the moisture absorption of the tape, there must be special equipment. We should consider the surface smooth, aluminum quality, glue content, moderate viscosity, etc. when we choose the composite sealing tape

If you are interested in more information about glass, welcome to visit our website: www.sggglassmanufactuer.com