- Browse Categories

-

Tempered glass

- Laminated glass

- Insulated Glass

- Curved glass

- Decorative Glass

- Architectural glass

- Glass Window & Door

- Glass Shower Door

- Glass Railing

- Glass Partition & Wall

- Glass Floor

- Glass Skylight/Canopy/Roof

- Glass Facade

- Padel Court

- Staircase System

- Glass Dome

- Glass Greenhouse

- Glass Elevator

- Special glass applications

- Float Glass

- Clear float glass

- Low Iron Glass

- Tinted float glass

- Reflective glass

- Low-E glass

- Patterned Glass

- Mirror Glass

- Furniture glass

- Glass Fittings

- Aluminium Veneer

- Horticultural Products

- Laminated glass

- Certifications

-

- Contact Us

- SHENZHEN SUN GLOBAL GLASS CO., LTD Address: 3F, QIHANG BUSINESS BUILDING, SHENFENG ROAD, LIUYUE, LONGGANG, SHENZHEN, GUANGDONG, CHINATel : 0086 755 84... Contact Now

- hot product

-

12mm fluted tempered glass, 1/2 inch low iron fluted toughened glass, 12mm fluted narrow reeded safety glass panel for interior decoration

CE standard complete padel tennis court glass price, full set portable paddle court tennis cost in China,Indoor and outdoor Padel Court construction systems for sale

broken glass table tops, shattered glass table tops, cracked glass table tops, 8mm 10mm 12mm 15mm tempered glass table tops

8mm ultra clear tempered fluted glass, toughened low iron decorated reeded glass, privacy interior glass for partition and bathroom

30mm tempered laminated glass floor manufacturer,10mm+10mm+10mm tempered laminated glass floor,30mm anti slip glass floor

12mm jumbo size clear tempered glass, 12mm jumbo size toughened safety glass,12mm tempered safety glass

10 mm clear tempered glass balustrade supplier, 10 mm toughened glass railings supplier, 3/8 inch tempered glass railings supplier

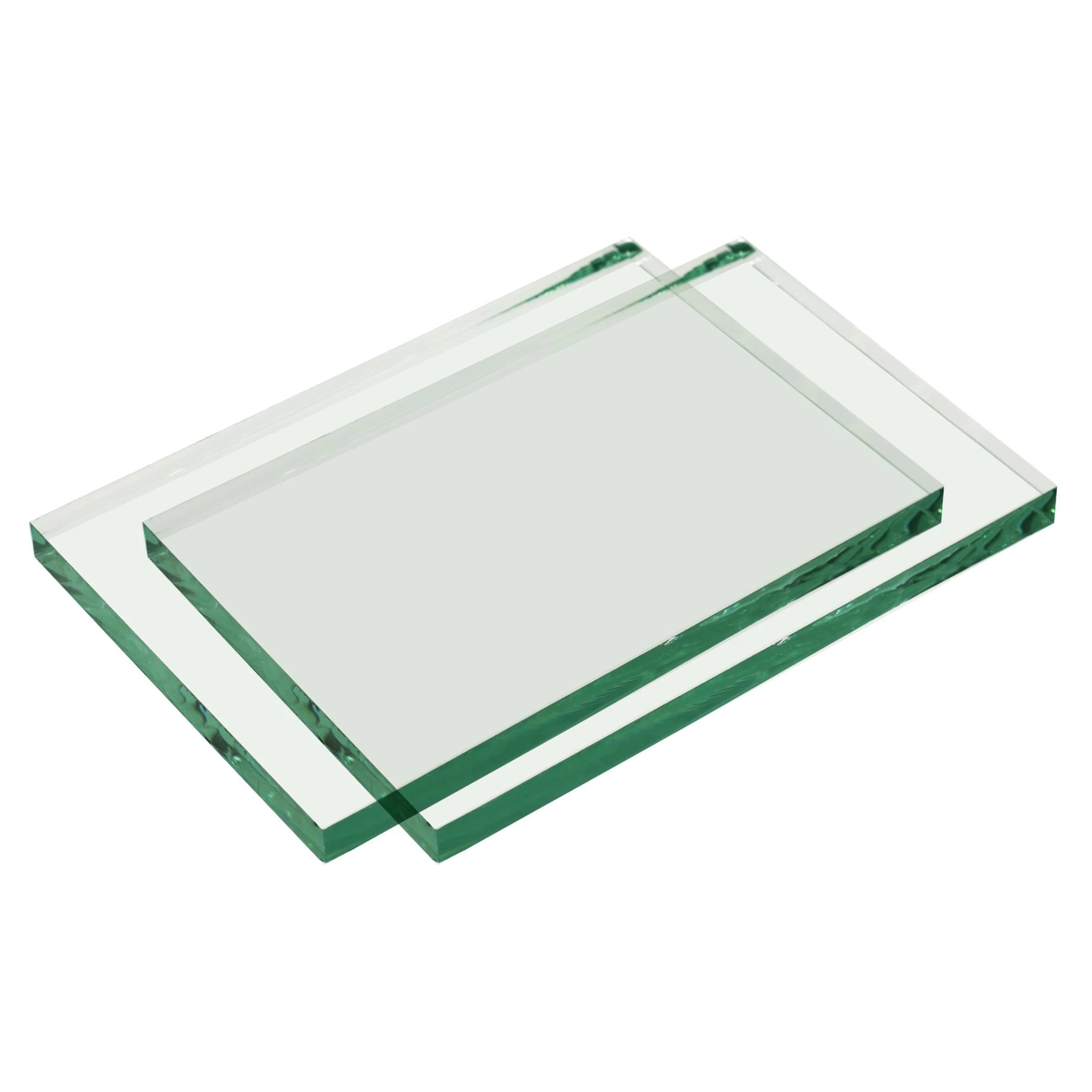

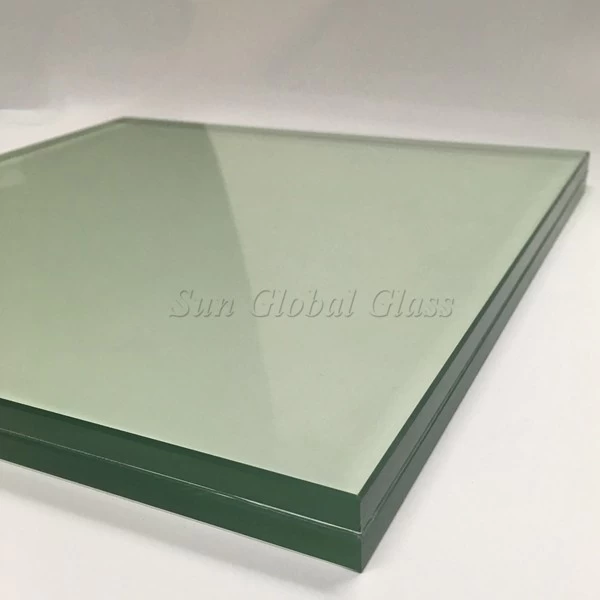

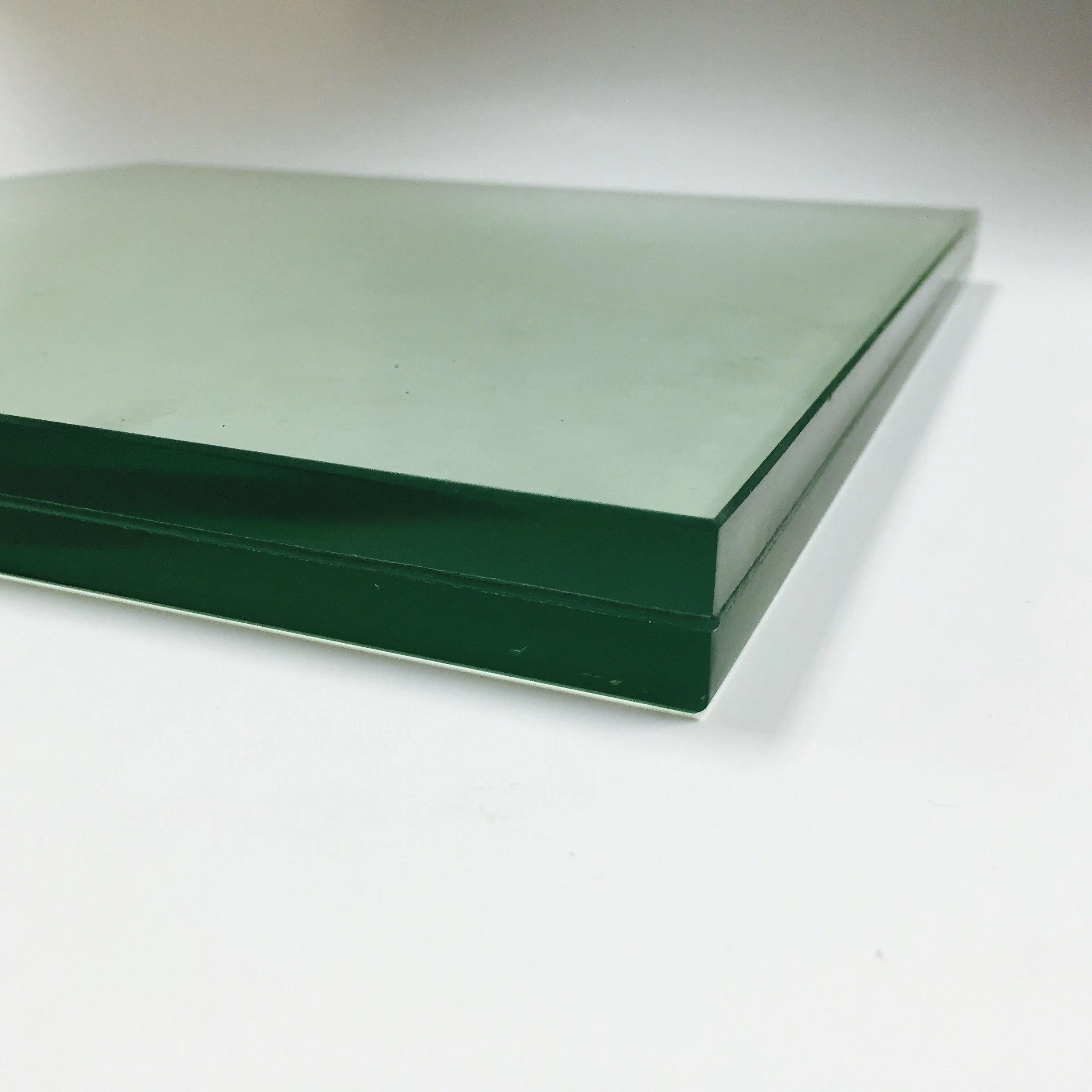

21.52mm laminated heat soak toughened glass panels, 10+10 laminated heat soak tempered glass, 21.52mm laminated heat soak glass panels

- Glass type: Heat soaked toughened glass / HST toughened glass / Heat-reinforced glass

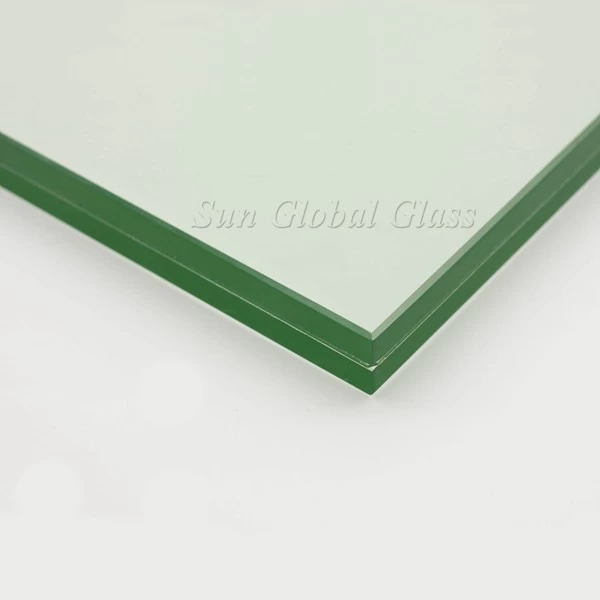

- Composition: 10mm HST tempered glass + 1.52 PVB + 10mm HST tempered glass

- Thickness: 21.52mm

- Color range: clear, extra clear, acid etched glass, tinted colors, printed colors and patterns

- Film option: EVA, PVB, SGP

- Glass size: custom size, maximum 8000mm in length

- Package: wooden crates for exportation

- Delivery: 10-15 days, urgent service available

SGG 21.52MM Laminated Heat Soaked Toughened Glass Supplier and Manufacturer in China

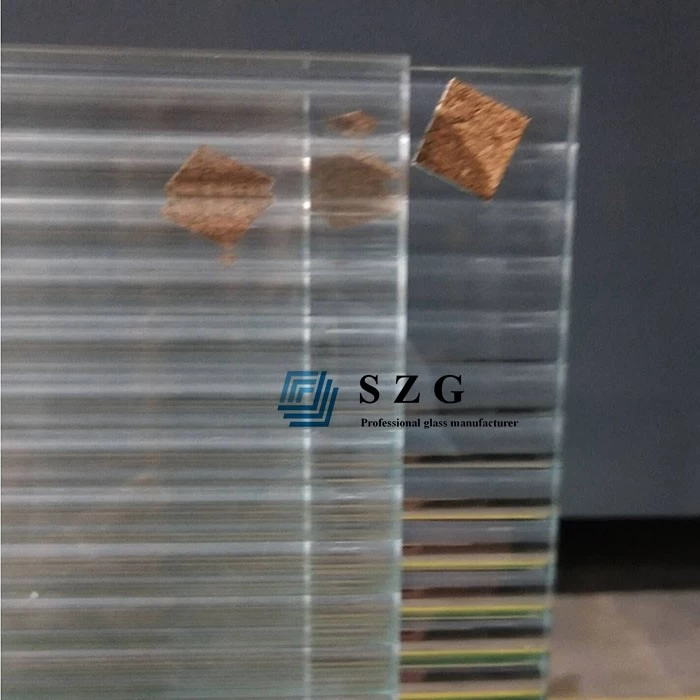

Heat soaked process is to reduce the risk of spontaneous breakage of tempered glass panels. To avoid of nickel sulfide (NiS) inclusion caused self-exploding in toughened glass, put glass in a heat soaking chamber for several hours at high temperature of 290℃. With this reinforced process, the glass panels contains Nis inclusion will broken in the chamber, instead of spontaneous broken after installed to buildings or furnitures. Heat soaked test could cause 93% tempered glass that contains NiS inclusions broken.

All kinds of tempered glass can be conducted with heat soaked process.

21.52mm Laminated heat soaked toughened glass is made of two panes of 10mm tempered glass plus 1.52mm PVB in the middle. The PVB is adhesive and elastic, to prevent glass break through. When tempered glass broken, those small glass fragments will be captured onto the film, instead of fall on to the ground. And the broken laminated glass is still a complate shape in window frame, provide continue protection before replacement arrived.

Heat Soaking Glass vs Toughened Glass

1. Tougheend glass has about 3‰ rate of spontaneous breakage, it occurs at uncertain time and place. Heat soaked glass is to reduce the spontaneous breakage before arriving at the field.

2. Heat soaked glass is possibility of lower strength than toughened glass.

3. Heat soaked glass can not totally avoid of spontaneous breakage.

Specifications of heat soaked laminated glass 21.51mm:

- Thickness: 21.52mm (10mm HST tempered glass + 1.52mm PVB + 10mm HST tempered glass)

- Color: clear, extra clear, frosted, tinted colors, printed color and pattern

- Size: custom size, maximum 8 meters in length

- Other thicknss: 13.14mm, 13.52mm, 17.52mm

Applications of heat soaked laminated glass 21.51mm:

- glass balustrade / glass railings / glass fence / glass handrail

- glass roof / glass skylight

- glass facade / glass curtain wall

- other glass glazing for high rise building

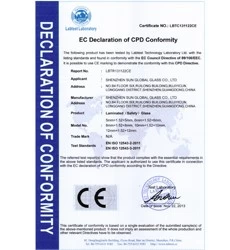

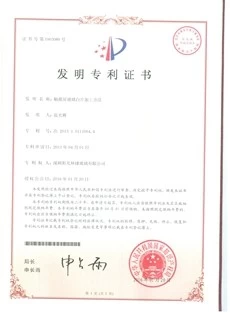

Quality of heat soaked laminated glass 21.51mm:

- EN standard

- CE mark

- ISO 9001-2015

Details of heat soaked laminated glass 21.51mm:

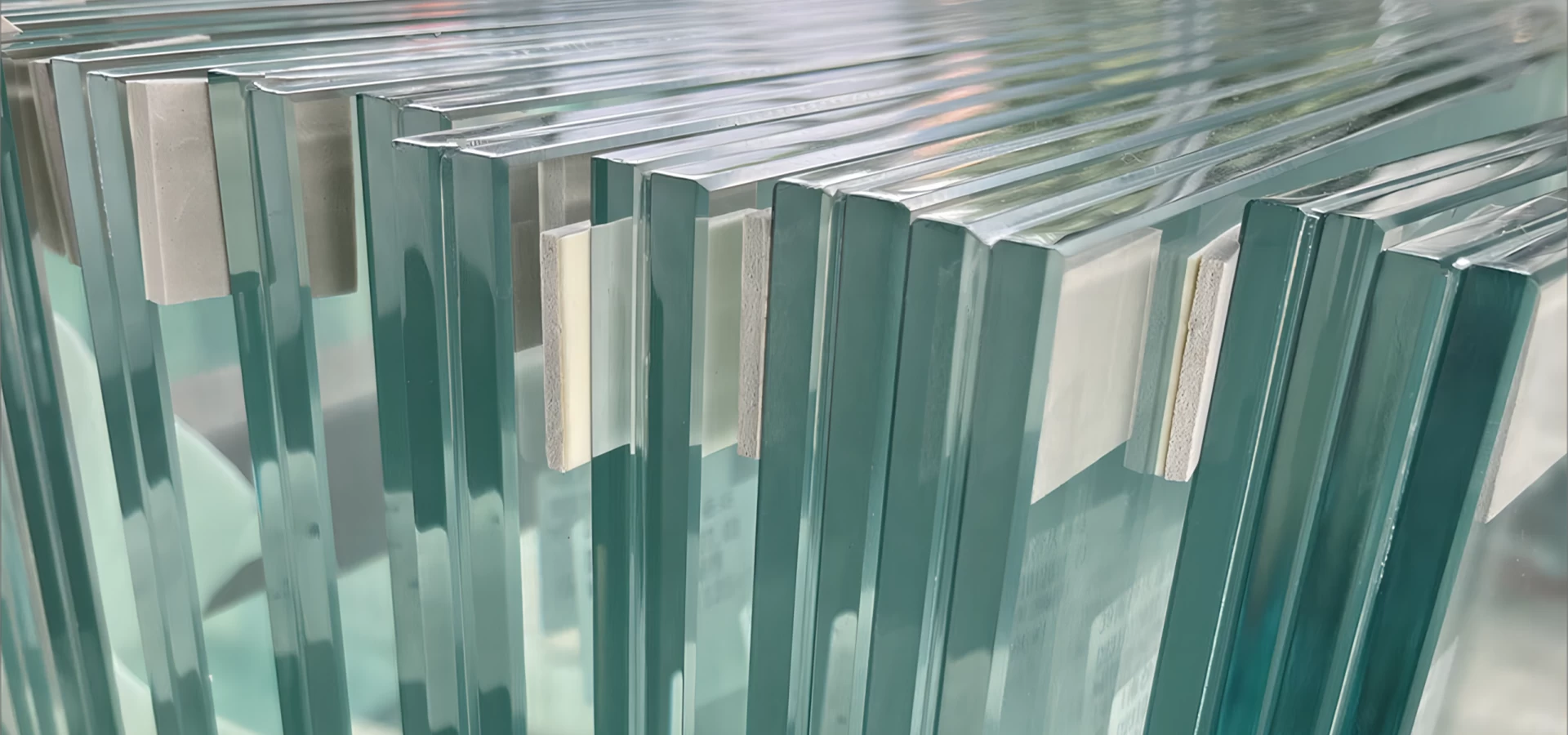

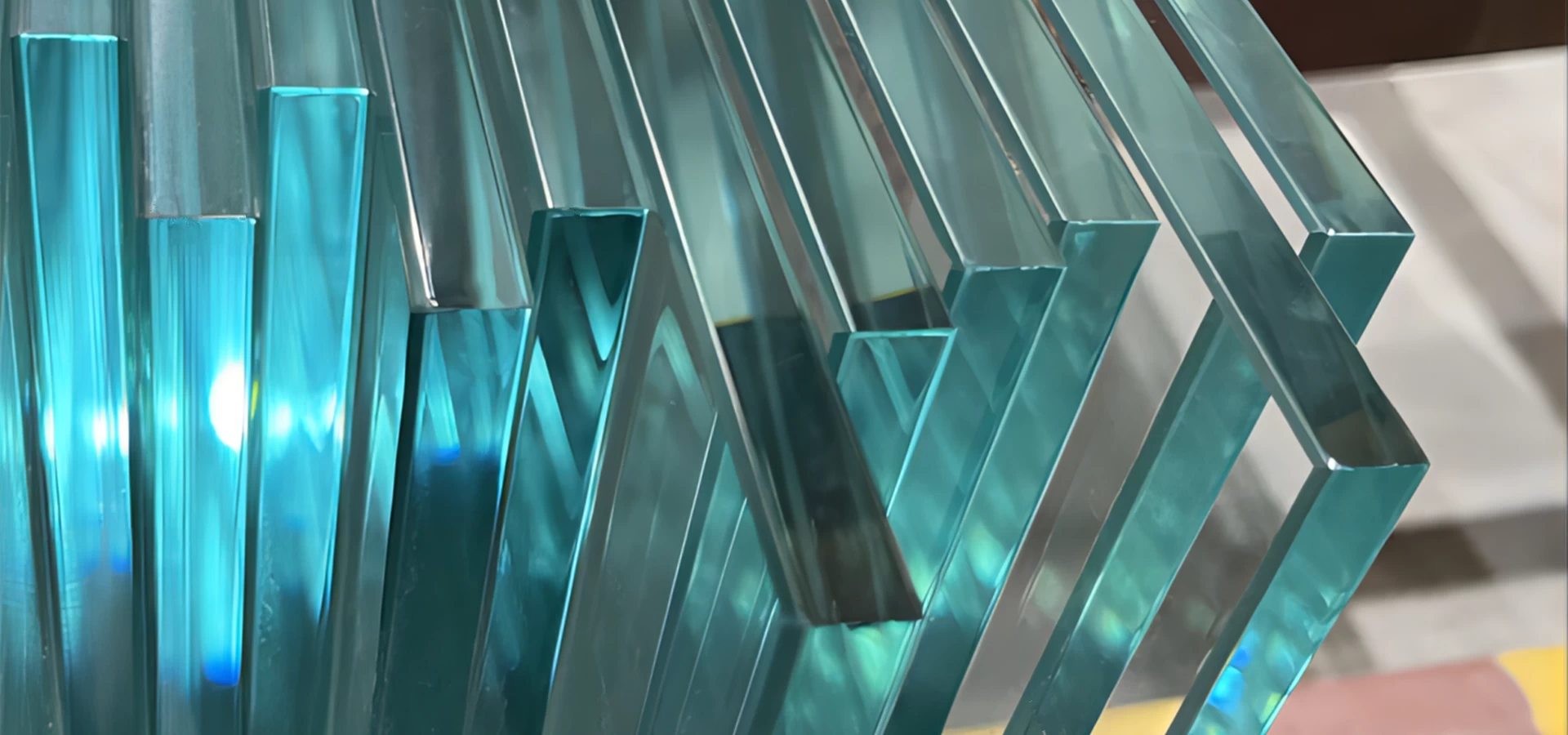

Product Pictures

Production Line:

Package and Loading: