How to improve float glass’s tempering rate?

KIM

www.sggglassmanufactuer.com

2017-08-31 19:52:43

How to improve float glass’s tempering rate?

As we all know, tempered glass are widely used in our daily life. More and more factory start to produce it. How to improve tempered glass yield which mentioned mostly in glass industry.

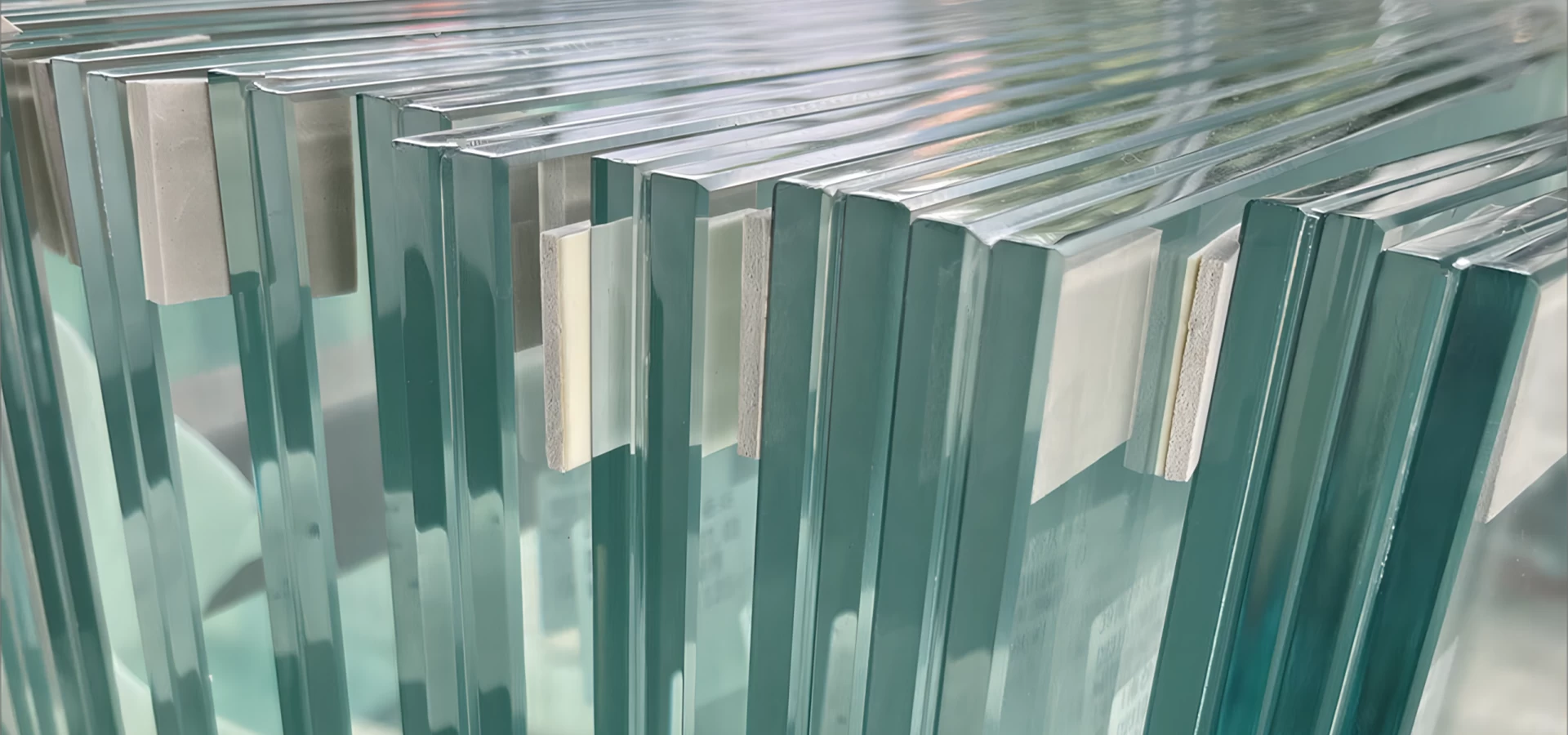

1.Edge work before tempered

The quality of edge work will affect the tempering rate greatly. Edge work will make glass aesthetic and unbroken during tempering. It improves the tempered rate a lot.

2.Control technological parameter during tempering

Several other factors will also affect the tempering rate such as heating temperature,heating time, cooling wind pressure and cooling time. Once confirm the heating time, heated to a reasonable temperature. The heating time are 40 seconds for each millimeter, but it will need more time(10%) to heat. If your tempered glass has drilling holes and cut outs. It will increase another time about 10%.

3.Uniform heating

Actually glass is a cubic.The surface of top side and bottom side are slowly in heating temperature.When the jumbo size glass for tempering, the center is harder to heat.

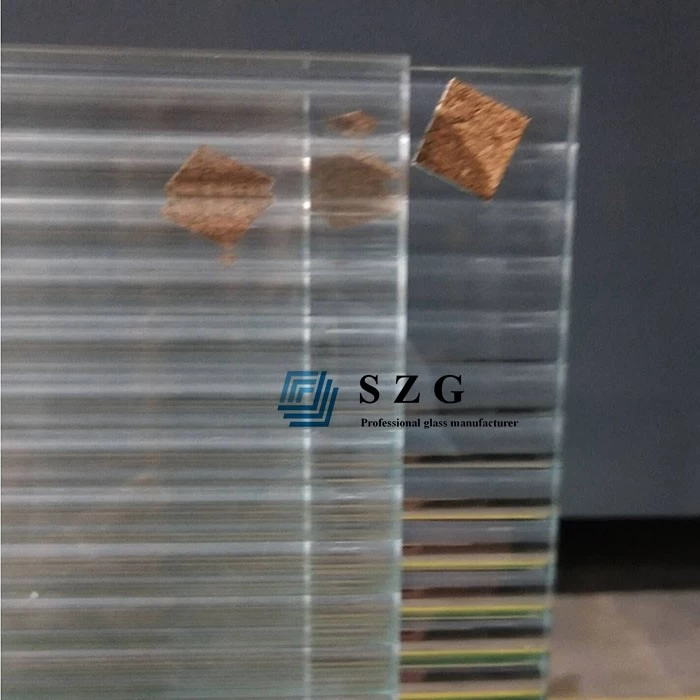

4.Drilling holes and cut outs

①radius of holes must thicker than glass thickness

②The distance between holes and glass side two times more than glass thickness.

③The distance between holes and holes should 2 times more than glass thickness.

Sun Global Glass produce 3MM tempered glass,4mm tempered glass ,5mm tempered glass,6mm tempered glass, 8mm tempered glass ,10mm tempered glass and 12mm tempered glass . 4-19 mm produced by thermal tempering. And 3mm glass produced by chemical tempering. 3mm chemical tempered glass mostly used as horologe

As we all know, tempered glass are widely used in our daily life. More and more factory start to produce it. How to improve tempered glass yield which mentioned mostly in glass industry.

1.Edge work before tempered

The quality of edge work will affect the tempering rate greatly. Edge work will make glass aesthetic and unbroken during tempering. It improves the tempered rate a lot.

2.Control technological parameter during tempering

Several other factors will also affect the tempering rate such as heating temperature,heating time, cooling wind pressure and cooling time. Once confirm the heating time, heated to a reasonable temperature. The heating time are 40 seconds for each millimeter, but it will need more time(10%) to heat. If your tempered glass has drilling holes and cut outs. It will increase another time about 10%.

3.Uniform heating

Actually glass is a cubic.The surface of top side and bottom side are slowly in heating temperature.When the jumbo size glass for tempering, the center is harder to heat.

4.Drilling holes and cut outs

①radius of holes must thicker than glass thickness

②The distance between holes and glass side two times more than glass thickness.

③The distance between holes and holes should 2 times more than glass thickness.

Sun Global Glass produce 3MM tempered glass,4mm tempered glass ,5mm tempered glass,6mm tempered glass, 8mm tempered glass ,10mm tempered glass and 12mm tempered glass . 4-19 mm produced by thermal tempering. And 3mm glass produced by chemical tempering. 3mm chemical tempered glass mostly used as horologe