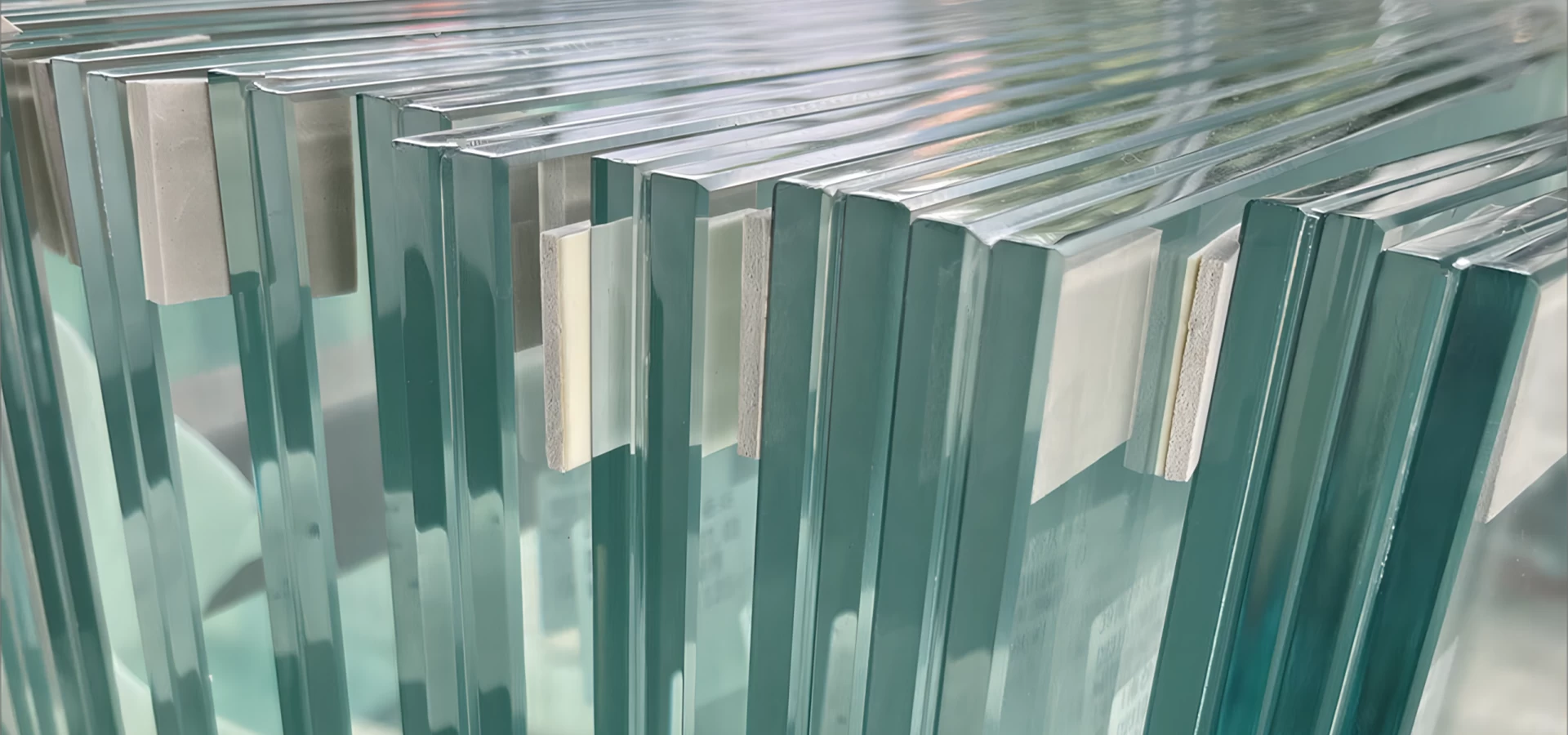

Step 1: Pack all float glass sheets by strong wooden crates, inserted with powder or paper

Step 2: Store glass in warehouse that dray and ventination, no glass will be stocked more than 6 months.

Step 3: Loading glass to container by rail hanger, ensure safety loading

Step 4: Fix all crates by steel belt, ensure no movement in container during transportation.

This packing type apply to standard sheet size of float glass: clear float glass, tinted float glass, reflective float glass, extra clear low iron float glass, acid etched frosted float glass, silver mirror float glass, aluminium mirror float glass, low-e float glass, and clear laminated glass.

Main standard size: 1830*2440, 2140*3300, 2140*3660, 2250*3300, 2440*3660, 1830*2600, and other standard size

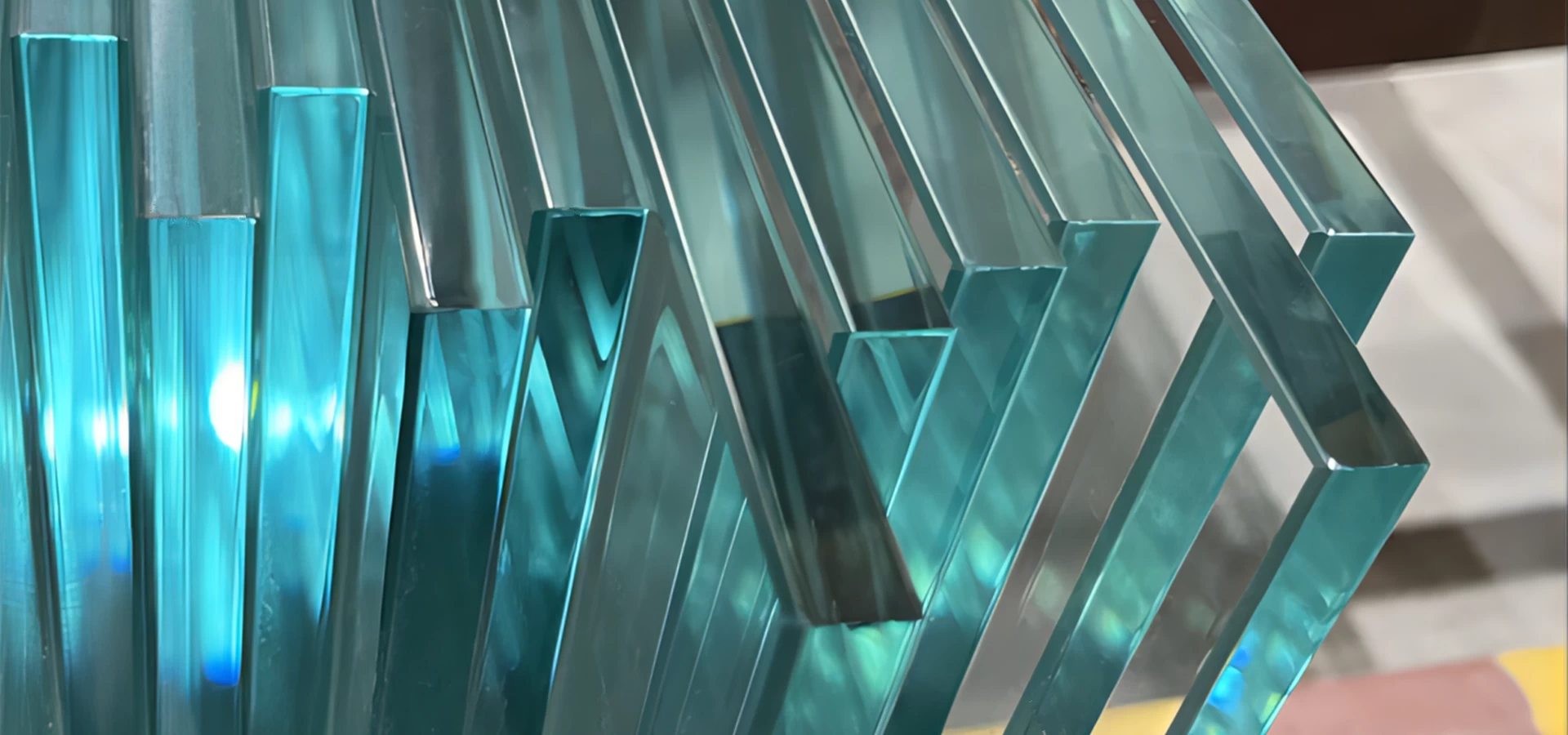

Step 1: Pack every piece of glass panels by bespoke wooden crates

Step 2: Consolidate package and wrapped the whole crate by plastic shrinkage, to proptect the surface of first and last piece in the crate

Step 3: Load crates into containers and fix by steel belt, to avoid of “moving” in the container dring transportation.

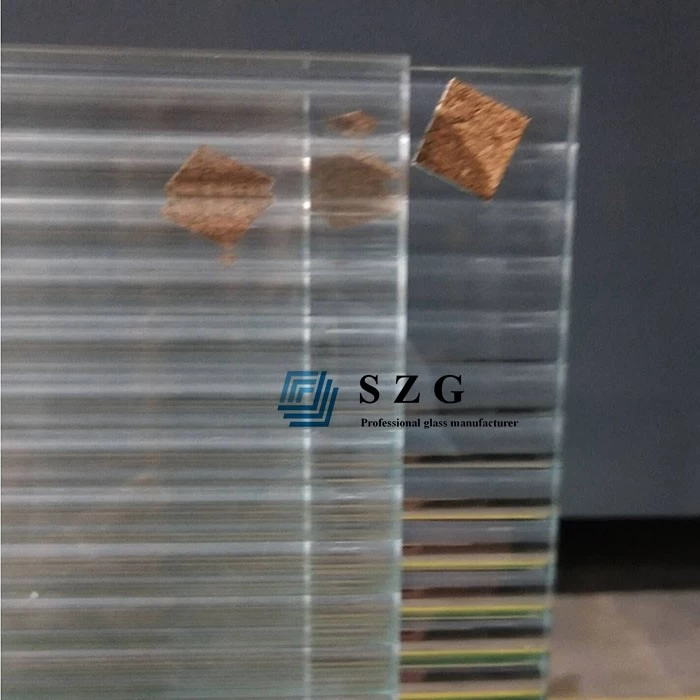

This packing type apply to: cut size and proceed glass, such as clear tempered glass, color toughened glass, tempered laminated glass, decorative beveled wall mirrors, low-e insulated glass, silk screen printing glass, frosted tempered glass, extra clear tempered glass, railing glass, balustrade glass, frameless tempered glass door, frameless bathroom mirror...and so on.