- Browse Categories

-

Tempered glass

- Laminated glass

- Insulated Glass

- Curved glass

- Decorative Glass

- Architectural glass

- Glass Window & Door

- Glass Shower Door

- Glass Railing

- Glass Partition & Wall

- Glass Floor

- Glass Skylight/Canopy/Roof

- Glass Facade

- Padel Court

- Staircase System

- Glass Dome

- Glass Greenhouse

- Glass Elevator

- Special glass applications

- Float Glass

- Clear float glass

- Low Iron Glass

- Tinted float glass

- Reflective glass

- Low-E glass

- Patterned Glass

- Mirror Glass

- Furniture glass

- Glass Fittings

- Aluminium Veneer

- Horticultural Products

- Laminated glass

- Certifications

-

- Contact Us

- SHENZHEN SUN GLOBAL GLASS CO., LTD Address: 3F, QIHANG BUSINESS BUILDING, SHENFENG ROAD, LIUYUE, LONGGANG, SHENZHEN, GUANGDONG, CHINATel : 0086 755 84... Contact Now

- hot product

-

12mm fluted tempered glass, 1/2 inch low iron fluted toughened glass, 12mm fluted narrow reeded safety glass panel for interior decoration

CE standard complete padel tennis court glass price, full set portable paddle court tennis cost in China,Indoor and outdoor Padel Court construction systems for sale

broken glass table tops, shattered glass table tops, cracked glass table tops, 8mm 10mm 12mm 15mm tempered glass table tops

8mm ultra clear tempered fluted glass, toughened low iron decorated reeded glass, privacy interior glass for partition and bathroom

30mm tempered laminated glass floor manufacturer,10mm+10mm+10mm tempered laminated glass floor,30mm anti slip glass floor

12mm jumbo size clear tempered glass, 12mm jumbo size toughened safety glass,12mm tempered safety glass

10 mm clear tempered glass balustrade supplier, 10 mm toughened glass railings supplier, 3/8 inch tempered glass railings supplier

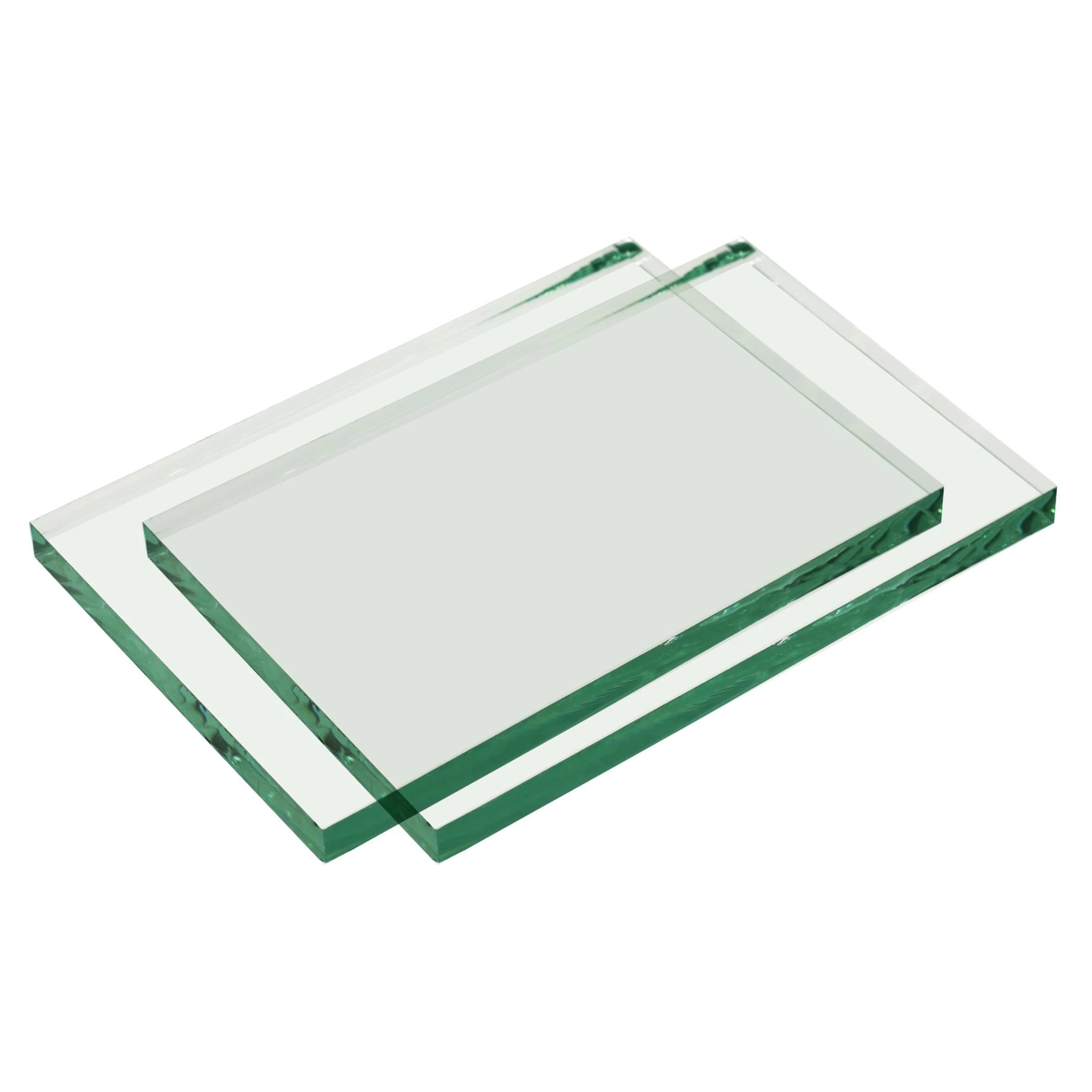

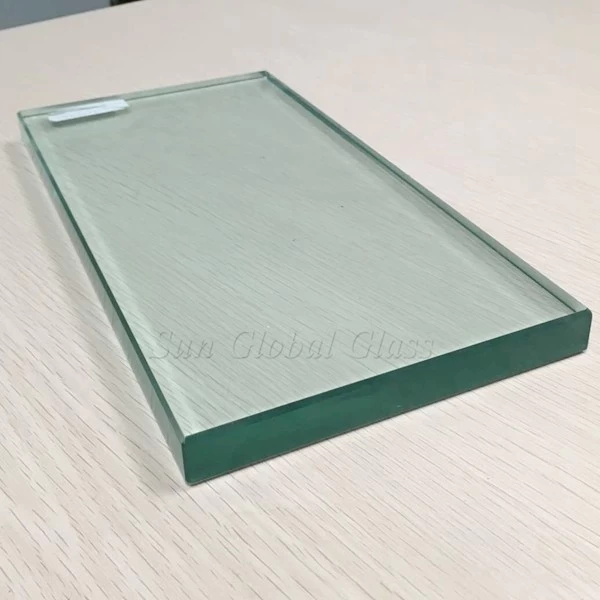

19mm toughened glass panels,19mm tempered glass panel,19mm clear tempered glass manufacturers

- Glass type:19mm toughened glass panels

- Other name: 19mm tempered glass / 19mm safety glass / 19mm ESG glass

- Thickness range: 4mm 5mm 6mm 8mm 9mm 10mm 12mm 15mm 19mm

- Size: cut to size, extra large size, bespoke size (minmum 300mm x300mm, maximum 8000mm)

- Color: clear, ultra clear, frosted, tinted colors, printed colors

- Package: safety exportation wood crates

- Delivery: 7-15 days, urgent service available

- Container: LCL, 20'GP

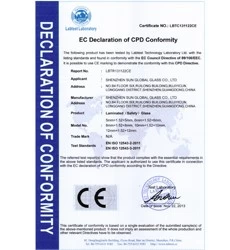

SGG 19MM TOUGHENED GLASS PANELS- CE EN12150 / BS 6206 /CCC Standard Quality

Please note that tempered glass can not be cut any more, even grinding edges, or other processing. Thus all design details of toughened glass must be confirmed before mass production. Like edge polishing, drilling holes, cut outs, etc.

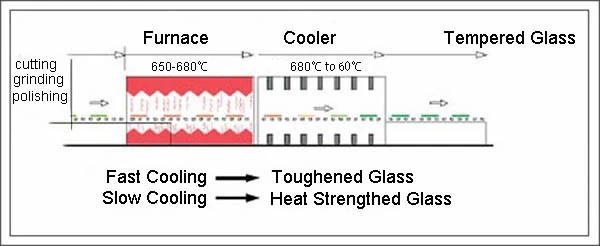

Tempered process:

1. physical tempered glass, also known as hardened tempered glass/strengthened tempered glass. It is putting ordinary flat glass in the heating furnace and heating the glass near softening temperature (600 ℃), through its own deformation to eliminate internal stress and then take the glass out of the furnace and use a long nozzle to high-pressure cold air blowing glass on both sides, so that it quickly and evenly cooled to room temperature, can be tempered glass. The glass is internally tension, externally stressed and when locally damaged, stress is released and the glass is broken into numerous small pieces that do not have sharp edges and corners.

2. chemical tempered glass by changing the glass surface of the chemical composition to improve the strength of the glass, the general application of exchange for tempered glass.

Degree of tempered:

1. Full tempered glass: tempered degree = 2 ~ 4N / cm, tempered glass surface stress α ≥ 95Mpa;

2. Half tempered glass: tempered degree = 2N / cm, semi-tempered glass surface stress 24Mpa ≤ α ≤ 69Mpa;

Featurers:

1, high impact strength, 5 times higher than ordinary glass

Applications:

Tempered glass is safety glass. Widely used in high-rise building doors and windows, glass curtain wall, interior partition glass, ceiling, elevator access, furniture, glass railing and so on. Usually tempered glass can be used in the following industries:

Specifications:

Sun Global Glass supply tempered glass with full range of colors, thickness and glass substrates.

1. Glass colors: clear, extra clear, frosted, bronze, gray, green, blue, reflective glass colors, printed colors, and low-E tempered glass.2. Glass thickness: 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm

3. Glass size: minimum size 300x300mm, maximum size length 8000mm

4. Edge work: Flat polished edge, chamfer edge, beveled edge, waved edge, OGEE edge, triple OG edge, and others.

5. Drilling holes: holes diameter need to be bigger than glass thickness.

6. Cut outs: all types of cut outs for different accessories. Our accurate cutting and measurements promoted the implementation of installers.

7. Safe corner: safety corner could greatly reduce the hurt to human by attack.

Quality:

1.19mm toughened glass panels meet BS 6206 UK safety glass standard.

2. 19mm toughened glass panels meet EN 12150 CE European safety glass standard.

3.19mm toughened glass panels meet Chinese Safety Glass Compulsory Certification (CCC)

4. High strength and puer clean surface. Select 40% of high quality clear glass for tempering.

5. Excellent work on details: smooth edge polishing, drilling holes tolerance +/- 0.9mm

6. Strong wooden crates package.

Product Details:

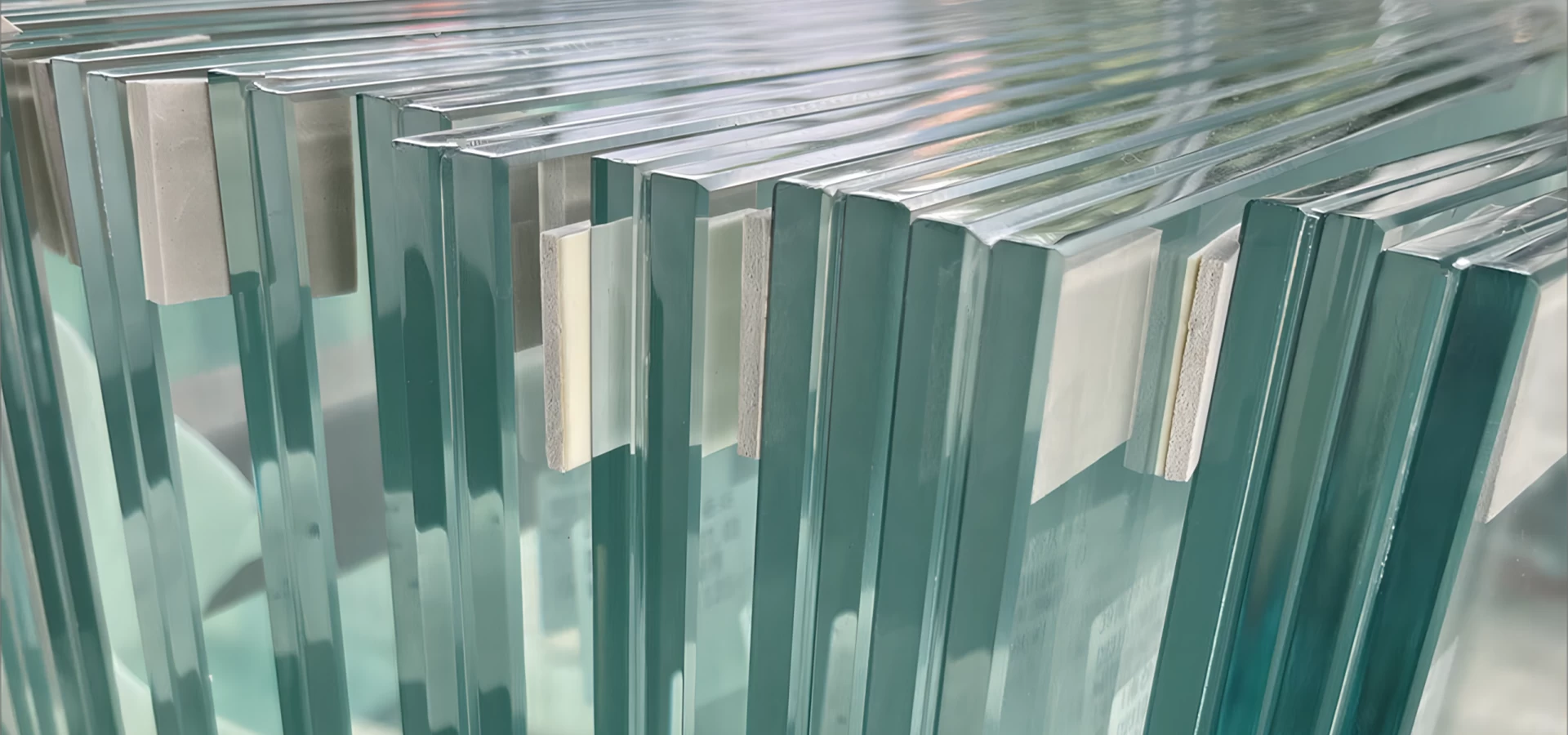

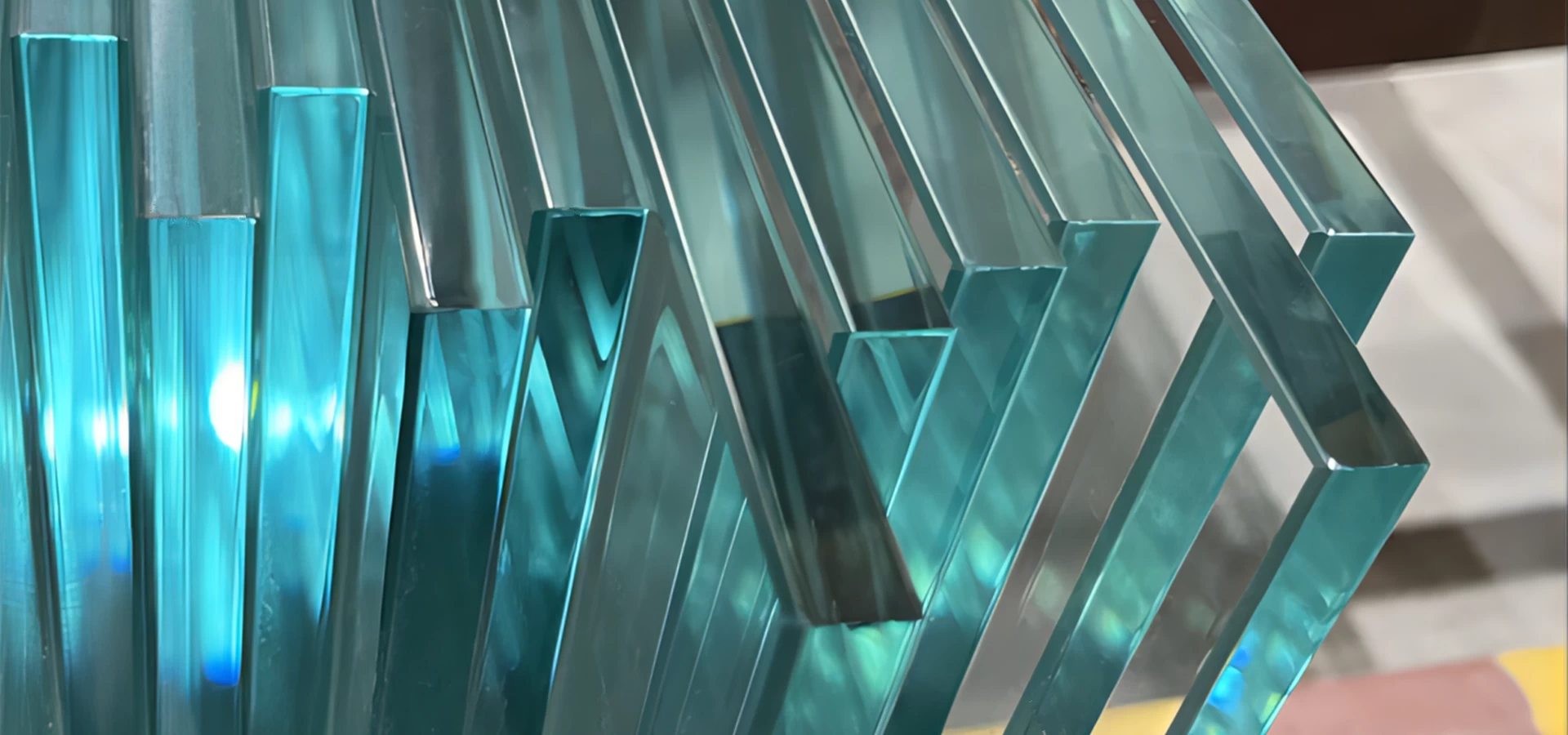

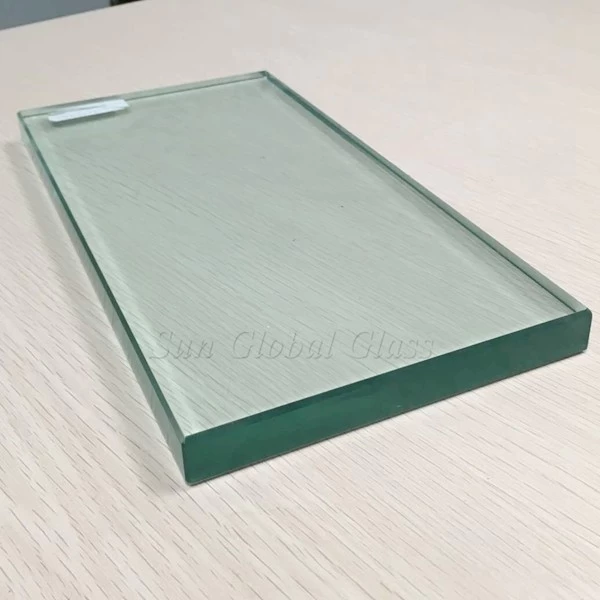

Product pictures of 19mm toughened glass panels:

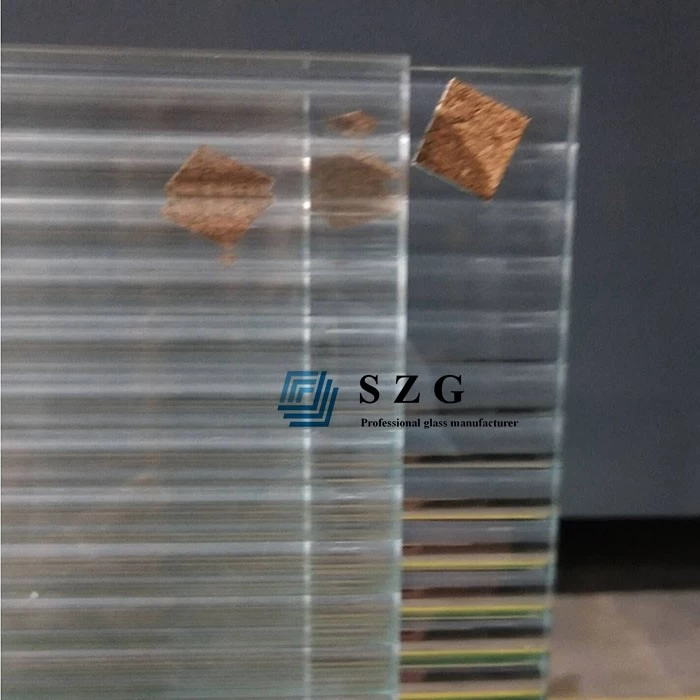

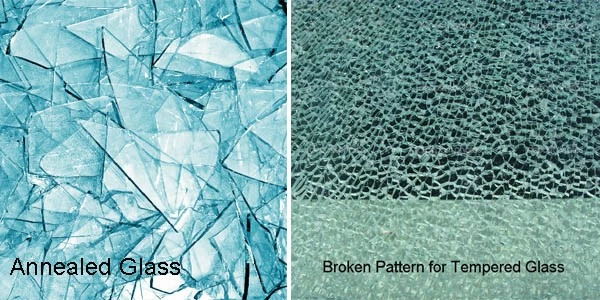

Differences between Annealed Glass and Tempered Glass:

1. 19mm toughened glass panels reduces the risk of injury due to its nature of breaking into small, circular pieces instead of sharp, jagged shards.

2. 19mm toughened glass panels is ease of clean-up if they ever do break.

3. 19mm toughened glass panels is 5 times strength than 19mm clear float glass.

Holes and Cut outs:

Production Line:

Package and Loading:

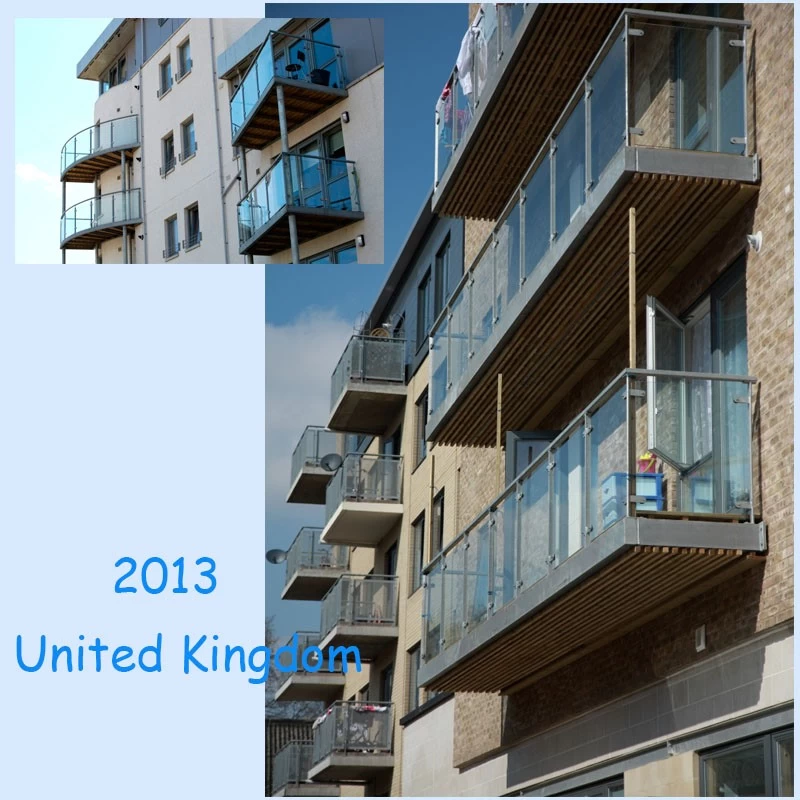

Our Projects:

Our promise is that you receiving 19mm toughened glass panels with high quality and safety condition from us.