How to deal with the flatness of tempered glass

kim

www.sggglassmanufactuer.com

2016-11-27 20:48:50

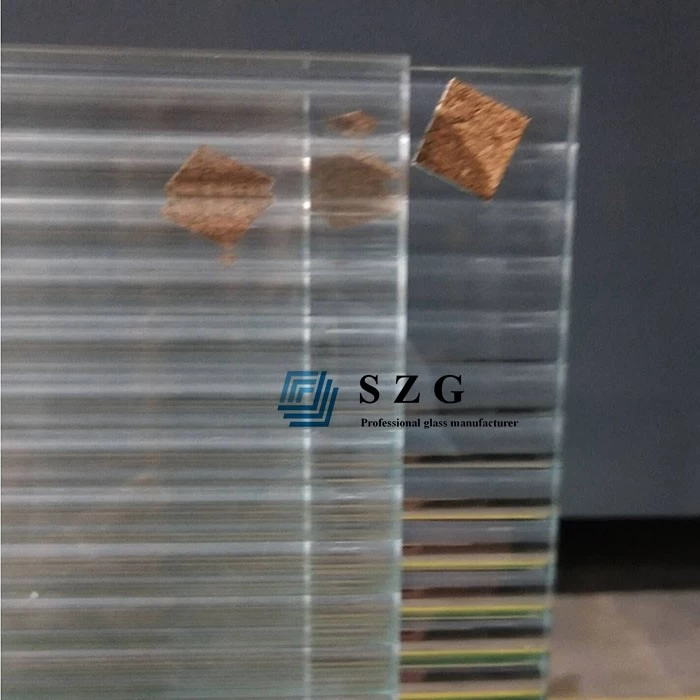

Poor glass flatness of the tempered glass roller from the main reasons include: the heating section roller and the cooling section roller bending deformation, heating section roller and the cooling section roller wear this aspect.

Wear of roller table in heating section of tempering furnace. In order to prevent the appearance of the pitting on the glass surface, we in the actual production, the heating section of the ceramic roller polished clean, fine sandpaper polished ceramic roll surface to clean off the surface of the ceramic roller adhesion impurities, Repeated cleaning of the roller table will lead to uneven wear and tear of the roller table, causing the same uneven thickness of the local roller, roller or eccentric. In addition, the roller and the roller between the sometimes due to different time to replace, because the new and old roller wear degree is different, will cause between the roller and roller thickness uneven. Above these, whether it is the thickness of the same roller table or roller eccentricity, or uneven thickness of the different roller, roller table will lead to uneven surface movement, the glass after heating to soften the temperature, in this uneven Roller surface transmission, will inevitably lead to deformation of the glass itself, affecting the final flatness of tempered glass.

Deformation of ceramic roll in heating section of tempering furnace.

The use of low-quality steel roller heating section will affect the smoothness of the glass, steel furnace heating section is made of fused silica and ceramic materials,

has good thermal shock resistance and thermal stability, but low-quality Of the ceramic roll its internal microstructure of the non-uniformity will lead to the roller at high temperature thermal deformation, thermal deformation caused by the roller table bending, thermal deformation of the roller in carrying the transmission glass, will cause deformation.

1.2, the heating section of the steel furnace and roller section of the roller wear section

In this case,

In this case,

Wear of roller table in heating section of tempering furnace. In order to prevent the appearance of the pitting on the glass surface, we in the actual production, the heating section of the ceramic roller polished clean, fine sandpaper polished ceramic roll surface to clean off the surface of the ceramic roller adhesion impurities, Repeated cleaning of the roller table will lead to uneven wear and tear of the roller table, causing the same uneven thickness of the local roller, roller or eccentric. In addition, the roller and the roller between the sometimes due to different time to replace, because the new and old roller wear degree is different, will cause between the roller and roller thickness uneven. Above these, whether it is the thickness of the same roller table or roller eccentricity, or uneven thickness of the different roller, roller table will lead to uneven surface movement, the glass after heating to soften the temperature, in this uneven Roller surface transmission, will inevitably lead to deformation of the glass itself, affecting the final flatness of tempered glass.