What matters need attention in Glass Blasting Processing?

Bella Zhang

www.sggglassmanufacturer.com

2016-10-28 09:16:03

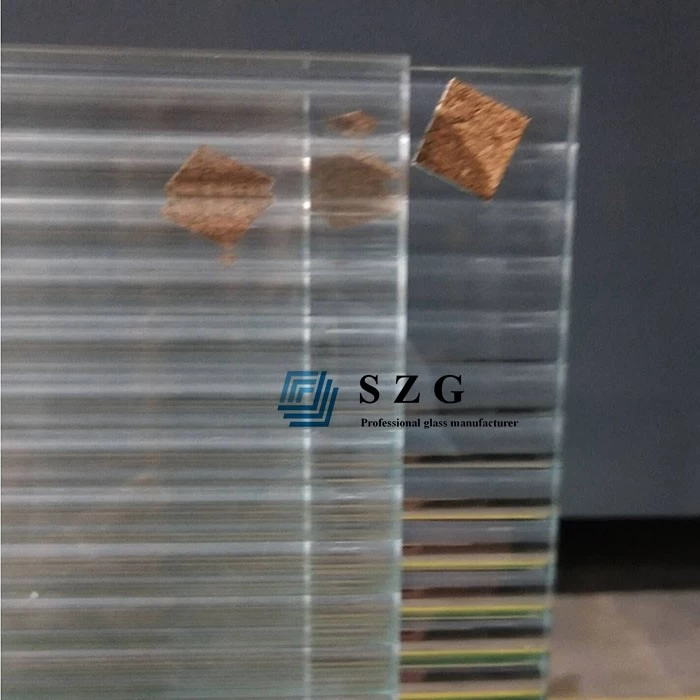

Sandblasting is one process to produce frosted glass, but there are many problems need attention during blasting progress.

What is sandblasting?

Sandblasting is the use of compressed air as the driving force to form a high-speed jet beam will be sprayed high-speed jet to the surface of the glass to be processed. Blasting the surface of the glass surface or shape changes, due to abrasive impact on the glass surface and cutting effect, so that the surface of the glass to obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the glass surface is improved, thus improving the fatigue resistance of the glass, Increasing the adhesion between it and the coating to extend the durability of the coating, but also conducive to leveling and decoration paint.

1, before work must wear protective equipment, not allowed to work naked arm. There shall be no less than two persons at work.

2, the gas tank, pressure gauges, safety valve to be regularly verified. The tank is drained twice a week and the filter in the sand tank is inspected once a month.

3, check the ventilation pipe and sandblasting door is sealed. Five minutes before work, ventilation and dust removal equipment shall be activated. When the ventilation and dust removal equipment fails, the work of the blasting machine shall be prohibited.

4, compressed air valve to open slowly, air pressure is not allowed to exceed 0.8MPa.

5, sand blasting size should be adapted to the requirements of the work, generally applicable between 10 to 20, sand should be kept dry.

7, not allowed to blow the body with compressed air dust or joke.

8, after the work, ventilation and dust removal equipment should continue to run for five minutes and then closed to discharge indoor dust to keep the venue clean.

9, the occurrence of personal and equipment accidents should be kept on-site and report the relevant departments.