- Browse Categories

-

Tempered glass

- Laminated glass

- Insulated Glass

- Curved glass

- Decorative Glass

- Architectural glass

- Glass Window & Door

- Glass Shower Door

- Glass Railing

- Glass Partition & Wall

- Glass Floor

- Glass Skylight/Canopy/Roof

- Glass Facade

- Padel Court

- Staircase System

- Glass Dome

- Glass Greenhouse

- Glass Elevator

- Special glass applications

- Float Glass

- Clear float glass

- Low Iron Glass

- Tinted float glass

- Reflective glass

- Low-E glass

- Patterned Glass

- Mirror Glass

- Furniture glass

- Glass Fittings

- Aluminium Veneer

- Horticultural Products

- Laminated glass

- Certifications

-

- Contact Us

- SHENZHEN SUN GLOBAL GLASS CO., LTD Address: 3F, QIHANG BUSINESS BUILDING, SHENFENG ROAD, LIUYUE, LONGGANG, SHENZHEN, GUANGDONG, CHINATel : 0086 755 84... Contact Now

- hot product

-

12mm fluted tempered glass, 1/2 inch low iron fluted toughened glass, 12mm fluted narrow reeded safety glass panel for interior decoration

CE standard complete padel tennis court glass price, full set portable paddle court tennis cost in China,Indoor and outdoor Padel Court construction systems for sale

broken glass table tops, shattered glass table tops, cracked glass table tops, 8mm 10mm 12mm 15mm tempered glass table tops

8mm ultra clear tempered fluted glass, toughened low iron decorated reeded glass, privacy interior glass for partition and bathroom

30mm tempered laminated glass floor manufacturer,10mm+10mm+10mm tempered laminated glass floor,30mm anti slip glass floor

12mm jumbo size clear tempered glass, 12mm jumbo size toughened safety glass,12mm tempered safety glass

10 mm clear tempered glass balustrade supplier, 10 mm toughened glass railings supplier, 3/8 inch tempered glass railings supplier

10MM Decorative Sandblasted Etched Glass, 10MM Obscure Sandblasting Glass, Cusotmized10MM Sandblasted Glass

- Specification:

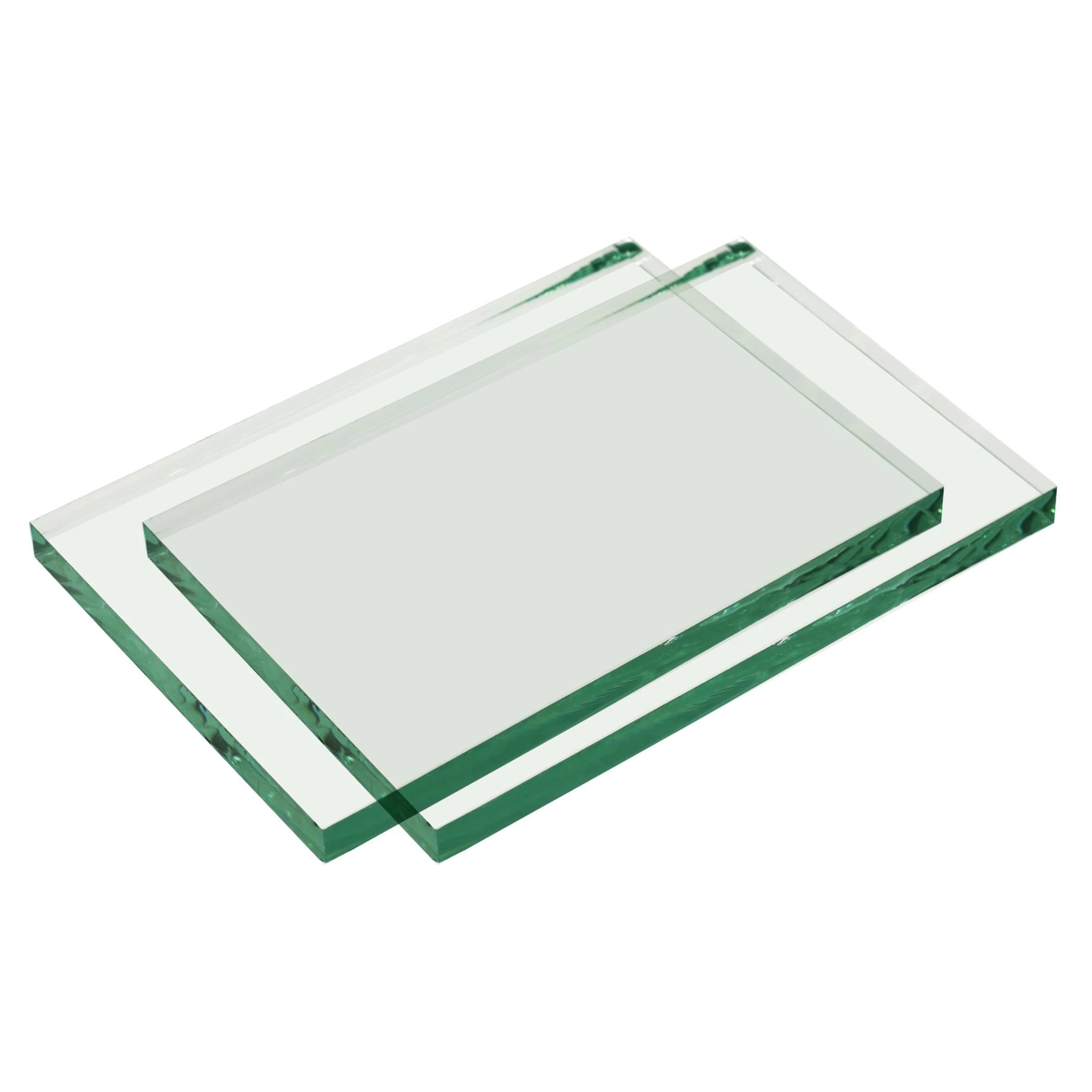

- 1.Glass thickness: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm

- 2.Glass substrate: clear float glass, ultra clear float glass and tinted glass

- 3.Size & shape: customized

- 4.Processing capacity: can be tempered, laminated, or insulated.

- 5.Glass packing: brand new, seaworthy plywood case with foam protection inside.

- 6.Production time: within 7 days, after payment received

- 7.Payment terms: T/T, L/C at sight.

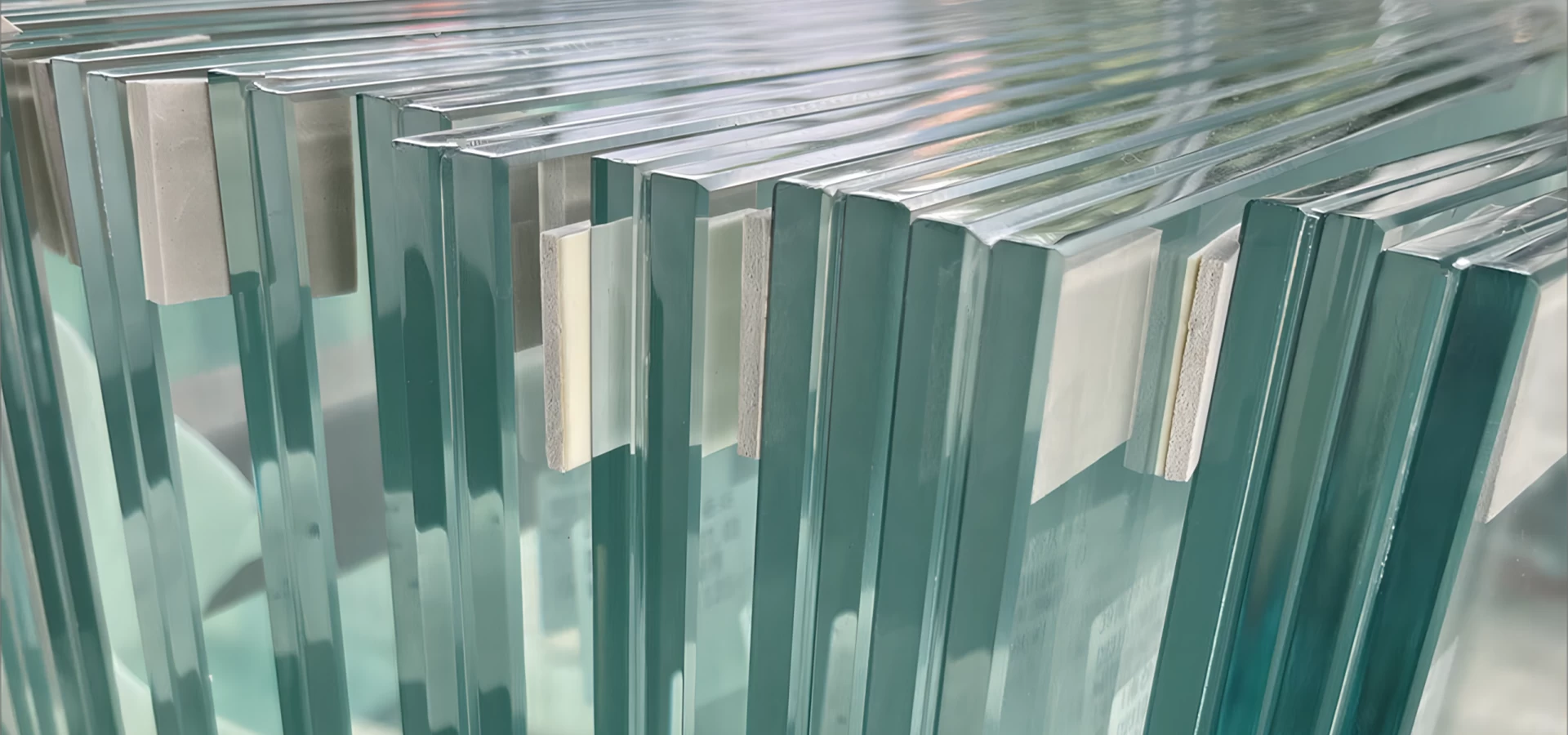

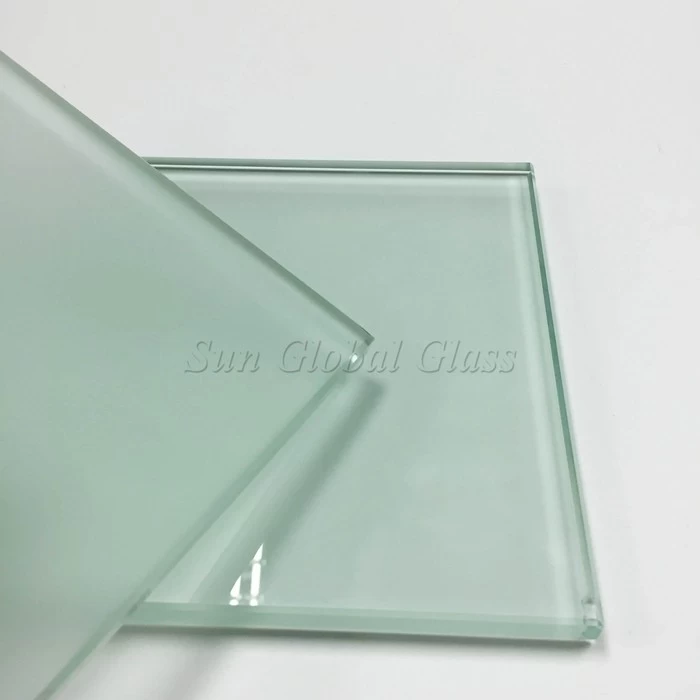

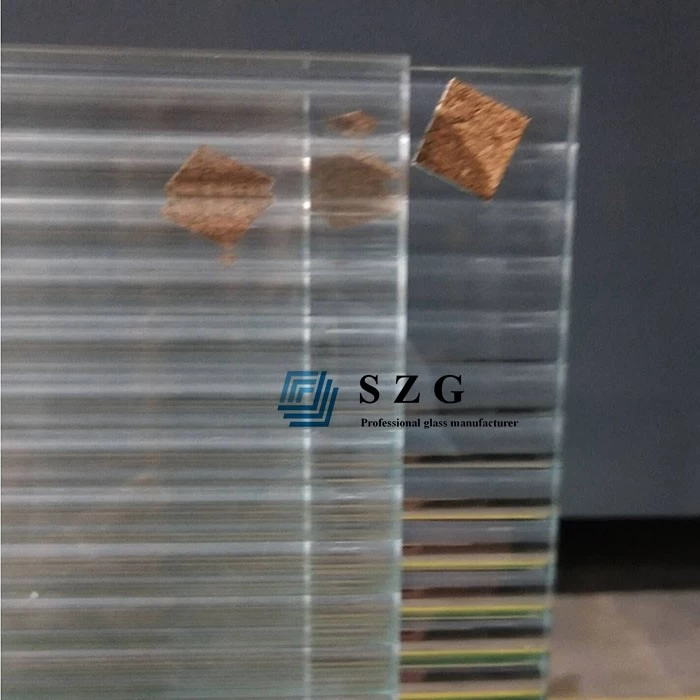

10MM Sandblasted Etched Glass can be tempered or laminated

Sand-blasted glass are done by high speed pressure-spraying sand blow on the glass surfaces. They offer versatility in creating design effects. First, people can choose a level of glass opaqueness from light, medium or heavy. Also, sandblasting makes it possible to "frost" sections of a glass shower, such as creating privacy strips or patterns.

Specification:

1.Glass thickness: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm

2.Glass substrate: clear float glass, ultra clear float glass and tinted glass

3.Size & shape: customized

4.Processing capacity: can be tempered, laminated, or insulated.

5.Glass packing: brand new, seaworthy plywood case with foam protection inside.

6.Production time: within 7 days, after payment received

7.Payment terms: T/T, L/C at sight.

In this section 10MM Sandblasting Glass can be produce by 10mm clear float glass, 10mm low iron float glass, or 10mm tinted glass. The procedure as below:

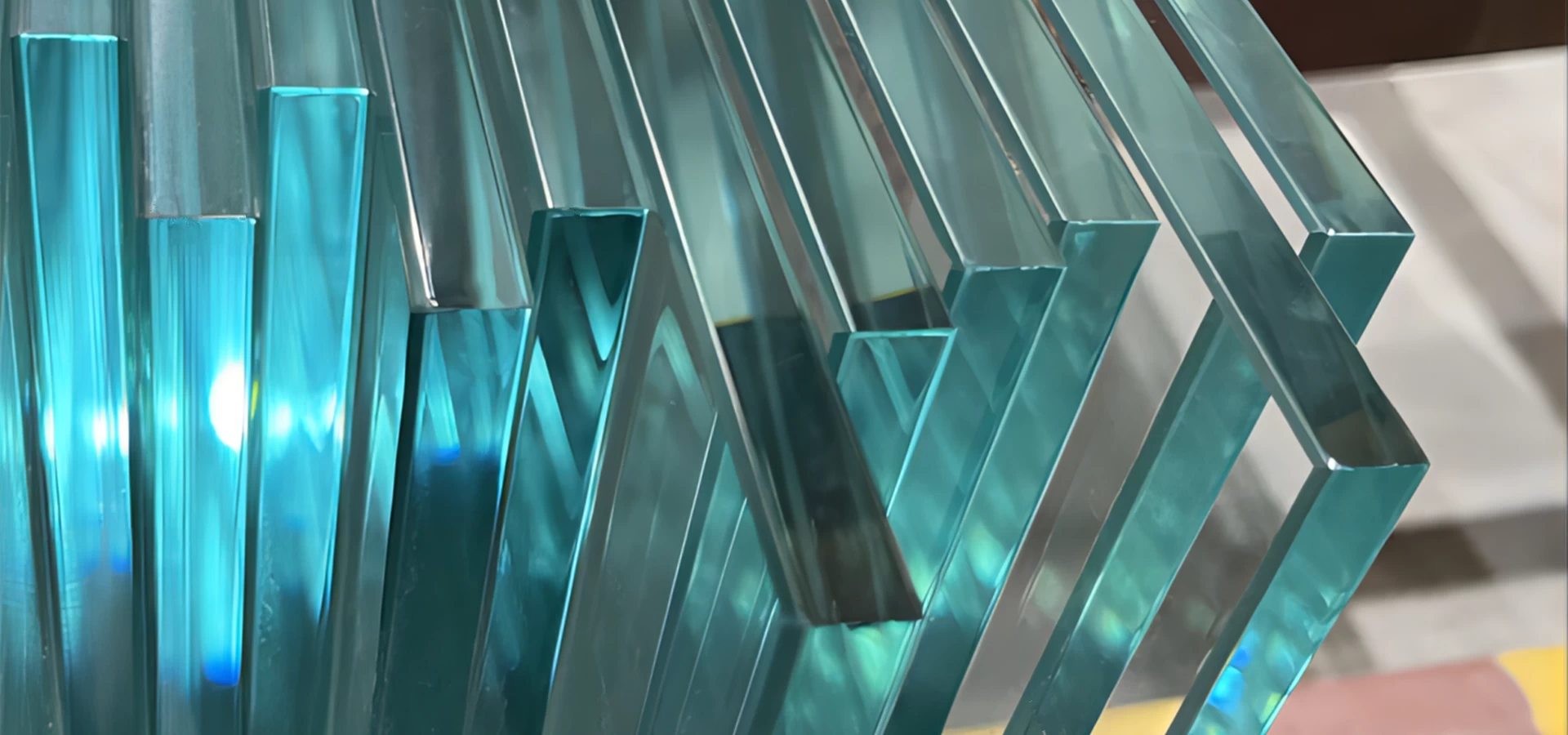

1.Inspect production materials: all these glass substrate must be high quality and have transparent appearance, no bubbles, no scratches, no mildew spot, etc.

2.Cutting glass into slices as per drawings, there are CNC cutting machines can realize accurate cutting.

3.propelling very fine bits of material at high-velocity to etch a surface. Sand is the most commonly used material, but any small, relatively uniform particles will work.

4.After sandblasted glass are finished, they can be do further processing to be sandblasted tempered glass, sandblasted etched toughened laminated glass, or sandblasting insulated glass, etc.

5.Inspect all sandblasting glass panels one by one before loading, to make sure each glass can meet projects’ demand.

6.Shenzhen Sun Global Glass Co., Limited can offer one-stop service for all clients, including:

Features:

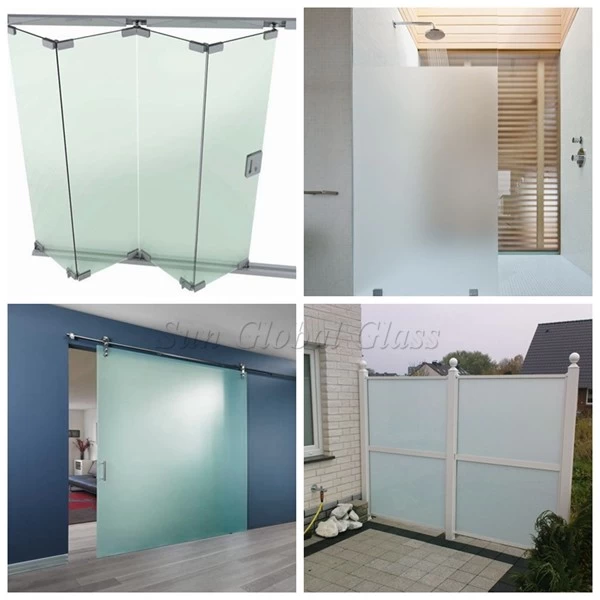

1.To obtain visual privacy while admitting light.

2.Sandblasting is used to frost an entire sheet of glass, for installation in places like bathrooms and other areas where people might want privacy.

3.Compare to acid etched glass, sandblasting is the glass is more likely to leave fingerprint marks which do require a bit more maintenance when it comes to cleaning.

Application:

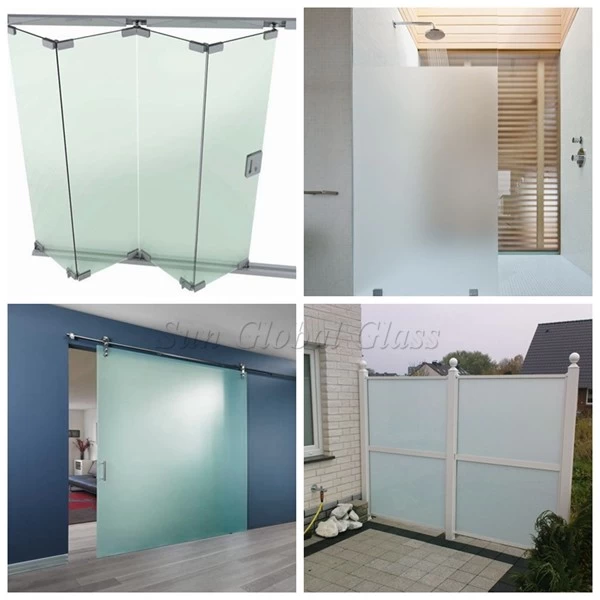

Sandblasted Glass door, windows, office partitions, etc.

Sand-blasted glass are done by high speed pressure-spraying sand blow on the glass surfaces. They offer versatility in creating design effects. First, people can choose a level of glass opaqueness from light, medium or heavy. Also, sandblasting makes it possible to "frost" sections of a glass shower, such as creating privacy strips or patterns.

Specification:

1.Glass thickness: 3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm

2.Glass substrate: clear float glass, ultra clear float glass and tinted glass

3.Size & shape: customized

4.Processing capacity: can be tempered, laminated, or insulated.

5.Glass packing: brand new, seaworthy plywood case with foam protection inside.

6.Production time: within 7 days, after payment received

7.Payment terms: T/T, L/C at sight.

In this section 10MM Sandblasting Glass can be produce by 10mm clear float glass, 10mm low iron float glass, or 10mm tinted glass. The procedure as below:

1.Inspect production materials: all these glass substrate must be high quality and have transparent appearance, no bubbles, no scratches, no mildew spot, etc.

2.Cutting glass into slices as per drawings, there are CNC cutting machines can realize accurate cutting.

3.propelling very fine bits of material at high-velocity to etch a surface. Sand is the most commonly used material, but any small, relatively uniform particles will work.

4.After sandblasted glass are finished, they can be do further processing to be sandblasted tempered glass, sandblasted etched toughened laminated glass, or sandblasting insulated glass, etc.

5.Inspect all sandblasting glass panels one by one before loading, to make sure each glass can meet projects’ demand.

6.Shenzhen Sun Global Glass Co., Limited can offer one-stop service for all clients, including:

drawing CAD for each glass panel, produce glass panels, purchase hardware, and other accessories, and so on.

Features:

1.To obtain visual privacy while admitting light.

2.Sandblasting is used to frost an entire sheet of glass, for installation in places like bathrooms and other areas where people might want privacy.

3.Compare to acid etched glass, sandblasting is the glass is more likely to leave fingerprint marks which do require a bit more maintenance when it comes to cleaning.

Application:

Sandblasted Glass door, windows, office partitions, etc.