- Browse Categories

-

Tempered glass

- Laminated glass

- Insulated Glass

- Curved glass

- Decorative Glass

- Architectural glass

- Glass Window & Door

- Glass Shower Door

- Glass Railing

- Glass Partition & Wall

- Glass Floor

- Glass Skylight/Canopy/Roof

- Glass Facade

- Padel Court

- Staircase System

- Glass Dome

- Glass Greenhouse

- Glass Elevator

- Special glass applications

- Float Glass

- Clear float glass

- Low Iron Glass

- Tinted float glass

- Reflective glass

- Low-E glass

- Patterned Glass

- Mirror Glass

- Furniture glass

- Glass Fittings

- Aluminium Veneer

- Horticultural Products

- Laminated glass

- Certifications

-

- Contact Us

- SHENZHEN SUN GLOBAL GLASS CO., LTD Address: 3F, QIHANG BUSINESS BUILDING, SHENFENG ROAD, LIUYUE, LONGGANG, SHENZHEN, GUANGDONG, CHINATel : 0086 755 84... Contact Now

- hot product

-

12mm fluted tempered glass, 1/2 inch low iron fluted toughened glass, 12mm fluted narrow reeded safety glass panel for interior decoration

CE standard complete padel tennis court glass price, full set portable paddle court tennis cost in China,Indoor and outdoor Padel Court construction systems for sale

broken glass table tops, shattered glass table tops, cracked glass table tops, 8mm 10mm 12mm 15mm tempered glass table tops

8mm ultra clear tempered fluted glass, toughened low iron decorated reeded glass, privacy interior glass for partition and bathroom

30mm tempered laminated glass floor manufacturer,10mm+10mm+10mm tempered laminated glass floor,30mm anti slip glass floor

12mm jumbo size clear tempered glass, 12mm jumbo size toughened safety glass,12mm tempered safety glass

10 mm clear tempered glass balustrade supplier, 10 mm toughened glass railings supplier, 3/8 inch tempered glass railings supplier

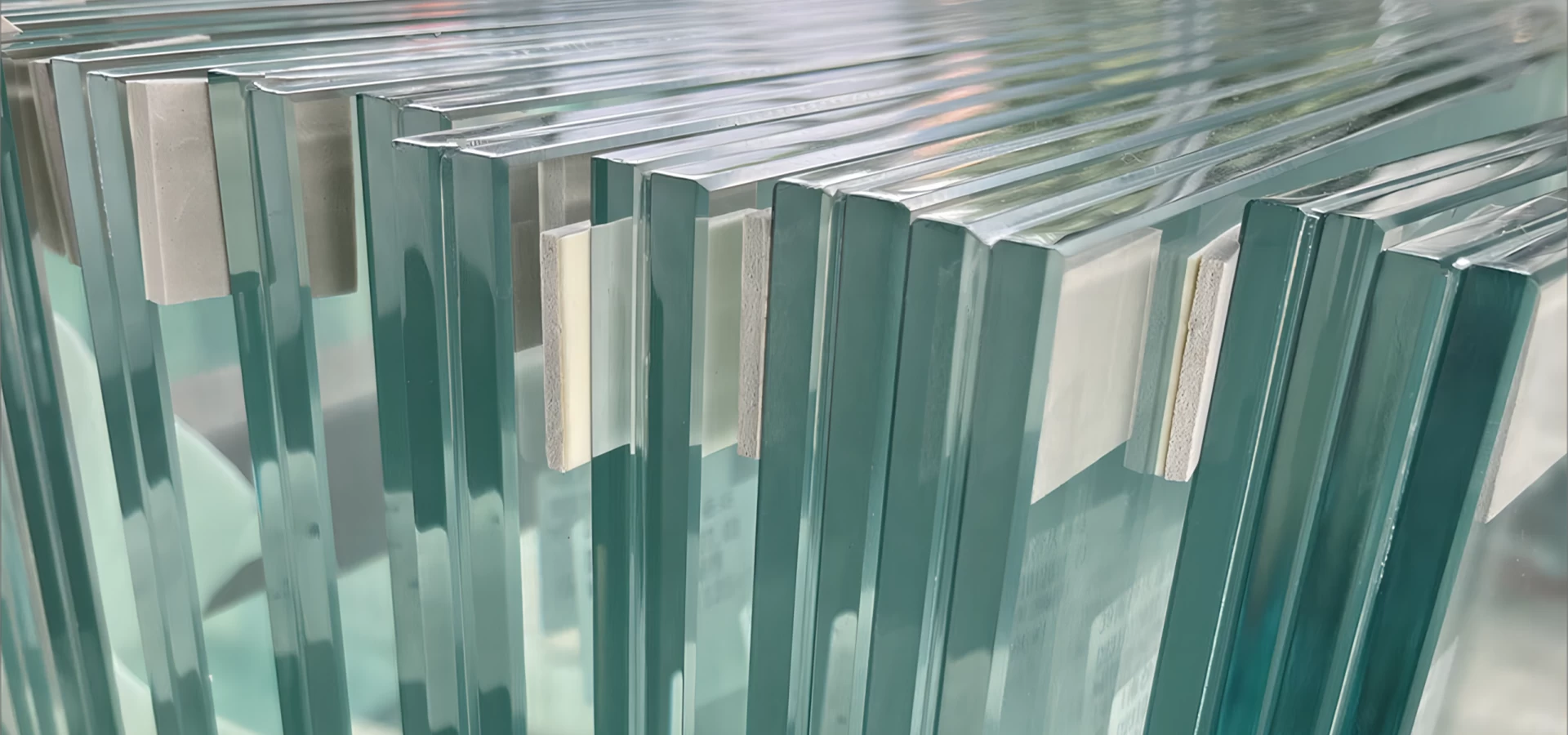

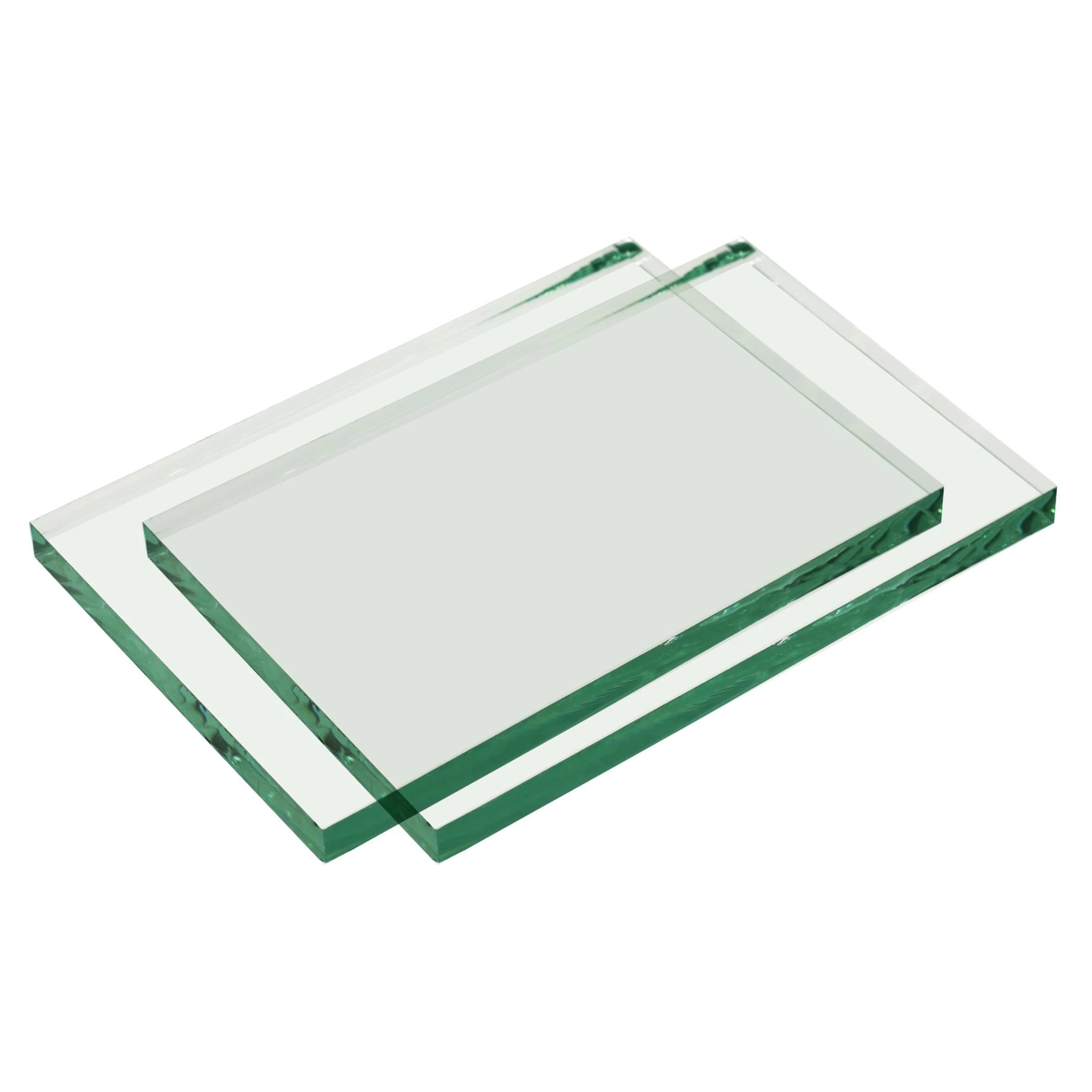

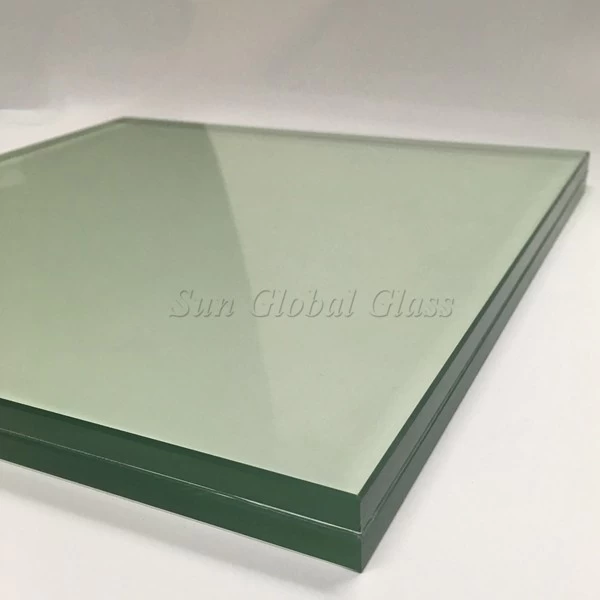

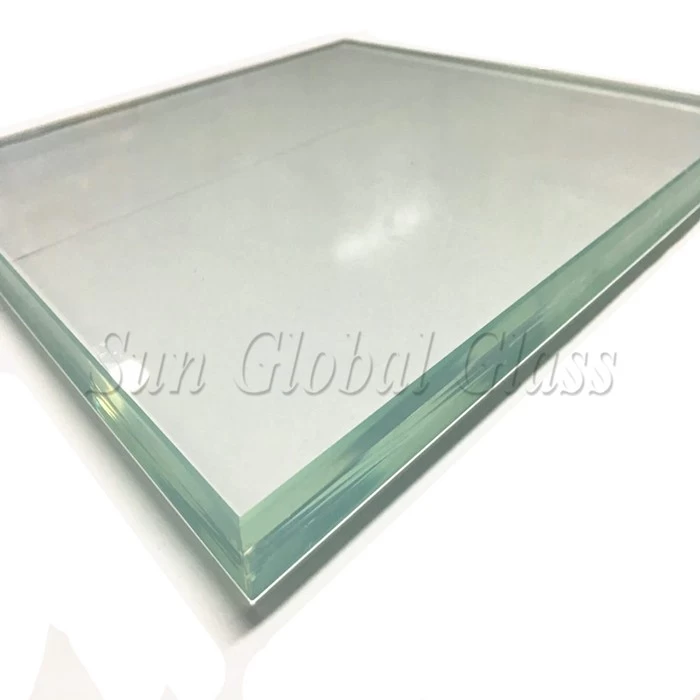

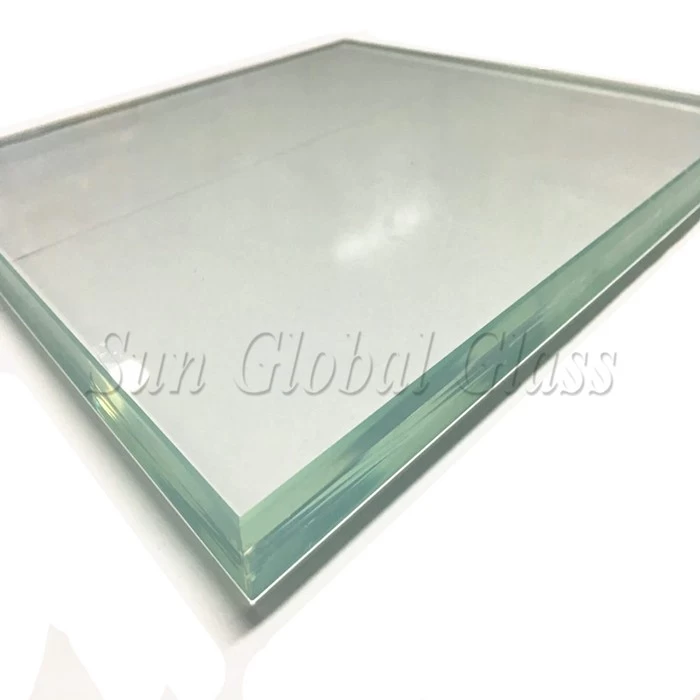

21.52mm HST Ultra clear low Iron tempered laminated glass, 10.10.4 heat soaked toughened low iron laminated glass, 21.52 thickness heat soaking test starphire glass toughened laminated glass

- Specification:

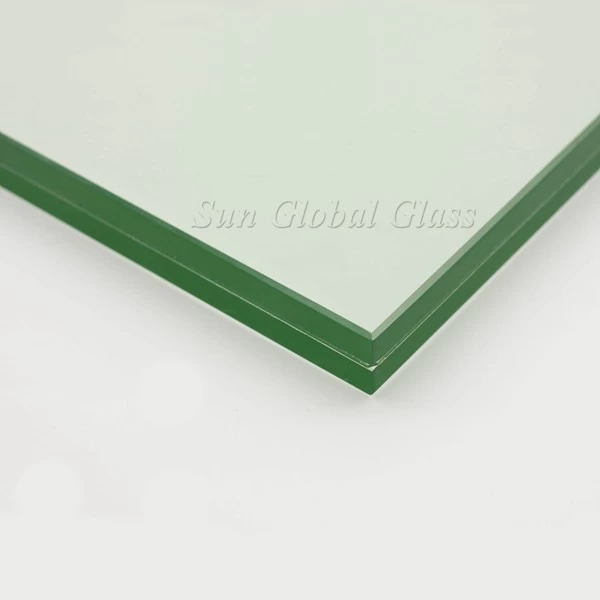

- 1.Glass name: 21.52mm HST toughened starphire glass laminated

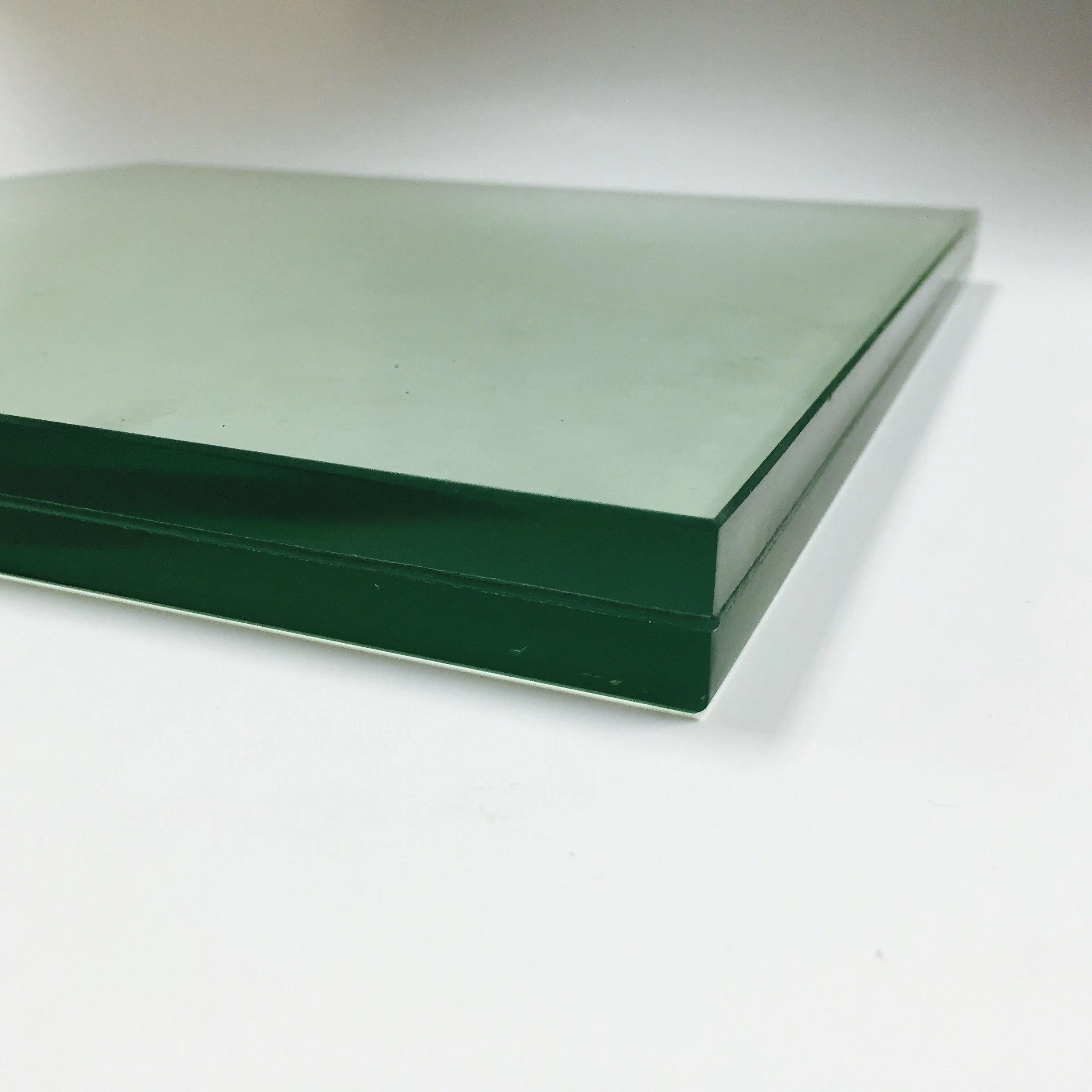

- 2.Glass combination: 2*10mm heat soaked toughened ultra clear glass

- 3.Interlayer film: 1.52mm PVB film, 1.52mm SGP film, 1.52mm EVA film, etc.

- 4.Glass size: any bespoke sizes, jumbo over size glass planes

- 5.Glass shape: both flat& curved shapes are available.

10mm Heat soaked tempered super white glass+1.52mm+10mmheat soaking toughened super white glass

Glass heat treatment contents full tempered glass, heat strengthened glass, and heat soaked testing glass (HST).

Shenzhen Sun Global Glass factory can carry on Heat soak testing of oversize jumbo architectural glass, for potential undesirable Nickel Sulfide inclusions, which may lead to potential spontaneous breakage. They have been applied into more and more public construction buildings, shopping malls, airports, hospitals, schools, etc.

As we known that the verification of hardened(tempered) glass by heat soak test is a best solution to reduce the spontaneous explosion of tempered glass( full tempered glass).

The main procedures of heat soaking glass as below:

1.the heating phase should be lasting for 3 hours, the temperature is 290℃.

2.heating in constant temperature, rise of nickel sulfides(SiN) particle volume under the influence of high temperature, then break of pane under the influence of internal stresses.

3.After cooling phase, unload the glass out from the heat soaked testing furnace, you can have perfect inspected glass panels.

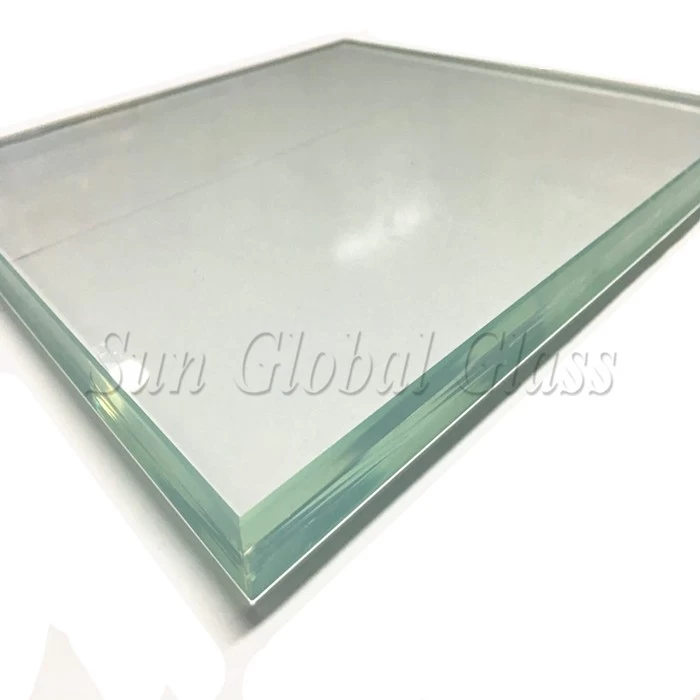

In this section 21.52mm Heat Soaked Low Iron Tempered Laminated Glass, the two layers of heat soak tested 10mm Ultra Clear Tempered Glass are bond by 1.52mm interlayer films together. Here 1.52mm interlayer film can be 1.52mm PVB film, 1.52mm SGP film, or 1.52mm EVA film, etc.

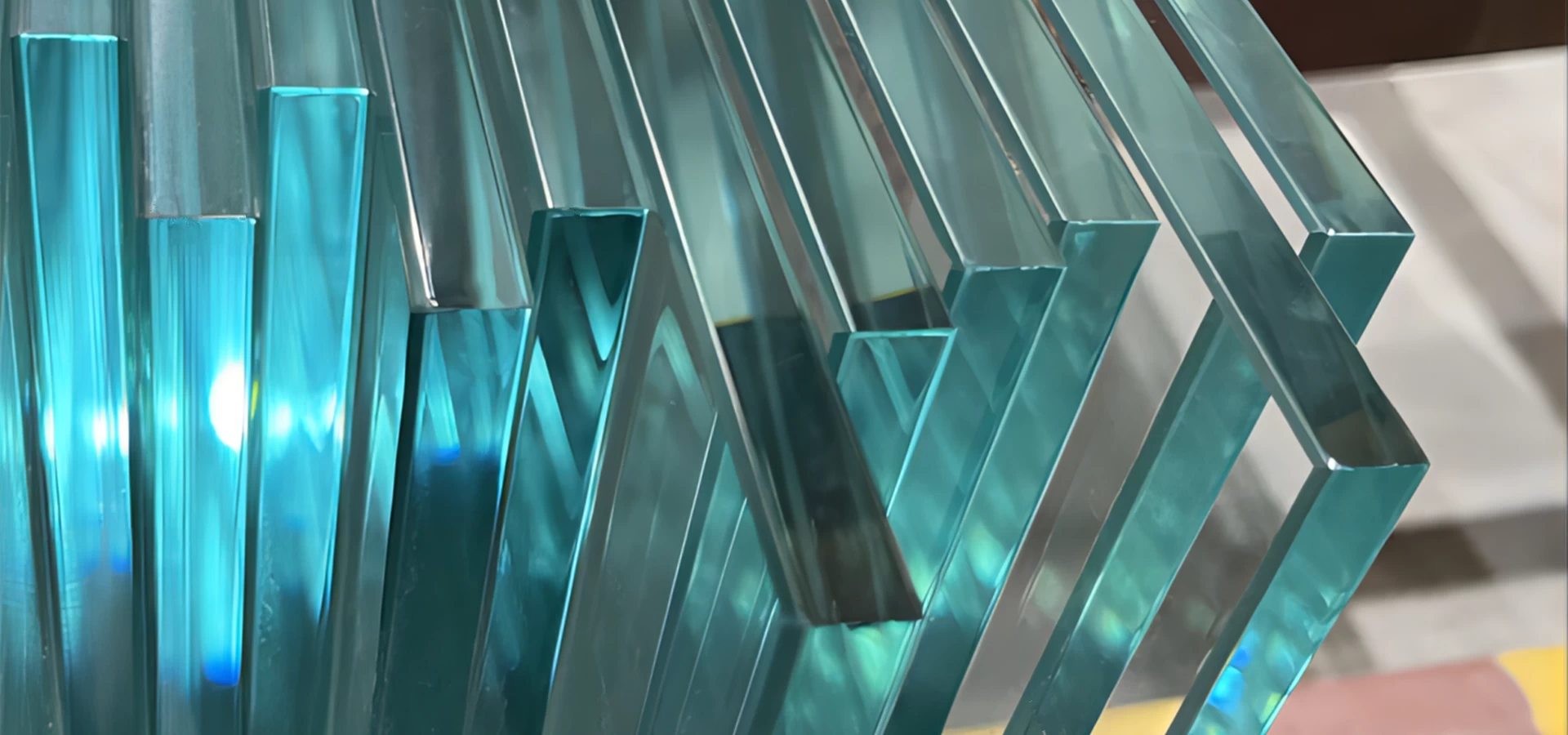

Specification:

1.Glass name: 21.52mm HST toughened starphire glass laminated

2.Glass combination: 2*10mm heat soaked toughened ultra clear glass

3.Interlayer film: 1.52mm PVB film, 1.52mm SGP film, 1.52mm EVA film, etc.

4.Glass size: any bespoke sizes, jumbo over size glass planes

5.Glass shape: both flat& curved shapes are available.

6.Other glass substrate options: heat soaking 10mm clear tempered glass; heat soaked testing 10mm tinted glass, heat soaked 10mm silkscreen glass, HST 10mm reflective glass, heat soaked test tempered 10mm Low E glass, etc.

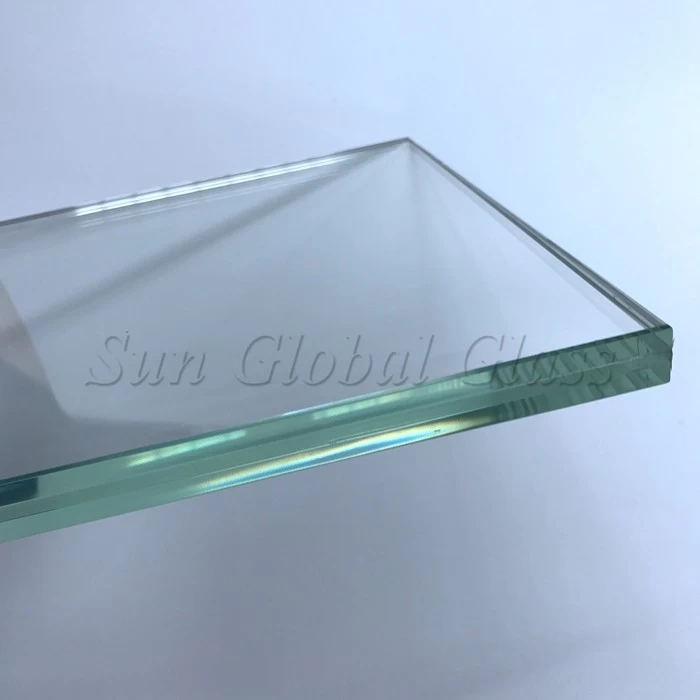

Features:

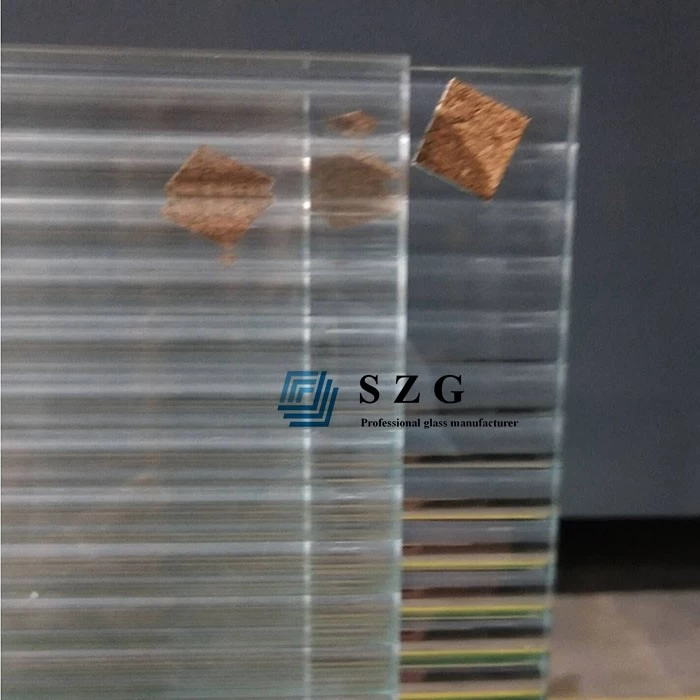

1.The heat soak processing reduces the incidence of spontaneous breakage in tempered glass caused by nickle sulphide.

2.21.52mm heat soaked tempered laminated ultra clear glass are ranked high end security glass, when the breakage occurs, the fragments would be adhered by interlayer films.

The more processing services we can do for you:

1.Drilled holes

2.Cut notches

3.Silkscreen with special pattern designs, or silkscreen borders

4.Acid etched with special designs

5.Polished edges, beveled edges, etc.

6.Any bespoke size or shape as per drawings.

The following applications should be considered for 10.10.4 heat soaking testing toughened super white glass:

1.Glass Structural Balustrades.

2.Glass Infill Balustrades – if fallout is an issue.

3.Sloped Overhead Glazing glass.

4.Glass Spandrels – if not Heat Strengthened.

5.Structural Glazing with Spider or other fittings.

6.Commercial Exterior Frameless Glass Doors, glass front doors

Glass heat treatment contents full tempered glass, heat strengthened glass, and heat soaked testing glass (HST).

Shenzhen Sun Global Glass factory can carry on Heat soak testing of oversize jumbo architectural glass, for potential undesirable Nickel Sulfide inclusions, which may lead to potential spontaneous breakage. They have been applied into more and more public construction buildings, shopping malls, airports, hospitals, schools, etc.

As we known that the verification of hardened(tempered) glass by heat soak test is a best solution to reduce the spontaneous explosion of tempered glass( full tempered glass).

The main procedures of heat soaking glass as below:

1.the heating phase should be lasting for 3 hours, the temperature is 290℃.

2.heating in constant temperature, rise of nickel sulfides(SiN) particle volume under the influence of high temperature, then break of pane under the influence of internal stresses.

3.After cooling phase, unload the glass out from the heat soaked testing furnace, you can have perfect inspected glass panels.

In this section 21.52mm Heat Soaked Low Iron Tempered Laminated Glass, the two layers of heat soak tested 10mm Ultra Clear Tempered Glass are bond by 1.52mm interlayer films together. Here 1.52mm interlayer film can be 1.52mm PVB film, 1.52mm SGP film, or 1.52mm EVA film, etc.

Specification:

1.Glass name: 21.52mm HST toughened starphire glass laminated

2.Glass combination: 2*10mm heat soaked toughened ultra clear glass

3.Interlayer film: 1.52mm PVB film, 1.52mm SGP film, 1.52mm EVA film, etc.

4.Glass size: any bespoke sizes, jumbo over size glass planes

5.Glass shape: both flat& curved shapes are available.

6.Other glass substrate options: heat soaking 10mm clear tempered glass; heat soaked testing 10mm tinted glass, heat soaked 10mm silkscreen glass, HST 10mm reflective glass, heat soaked test tempered 10mm Low E glass, etc.

Features:

1.The heat soak processing reduces the incidence of spontaneous breakage in tempered glass caused by nickle sulphide.

2.21.52mm heat soaked tempered laminated ultra clear glass are ranked high end security glass, when the breakage occurs, the fragments would be adhered by interlayer films.

The more processing services we can do for you:

1.Drilled holes

2.Cut notches

3.Silkscreen with special pattern designs, or silkscreen borders

4.Acid etched with special designs

5.Polished edges, beveled edges, etc.

6.Any bespoke size or shape as per drawings.

The following applications should be considered for 10.10.4 heat soaking testing toughened super white glass:

1.Glass Structural Balustrades.

2.Glass Infill Balustrades – if fallout is an issue.

3.Sloped Overhead Glazing glass.

4.Glass Spandrels – if not Heat Strengthened.

5.Structural Glazing with Spider or other fittings.

6.Commercial Exterior Frameless Glass Doors, glass front doors

Production:

Packing & Loading