Toughened glass production procedure

Alice

www.sggglassmanufacturer.com

2017-03-08 22:04:17

Toughened glass production procedure

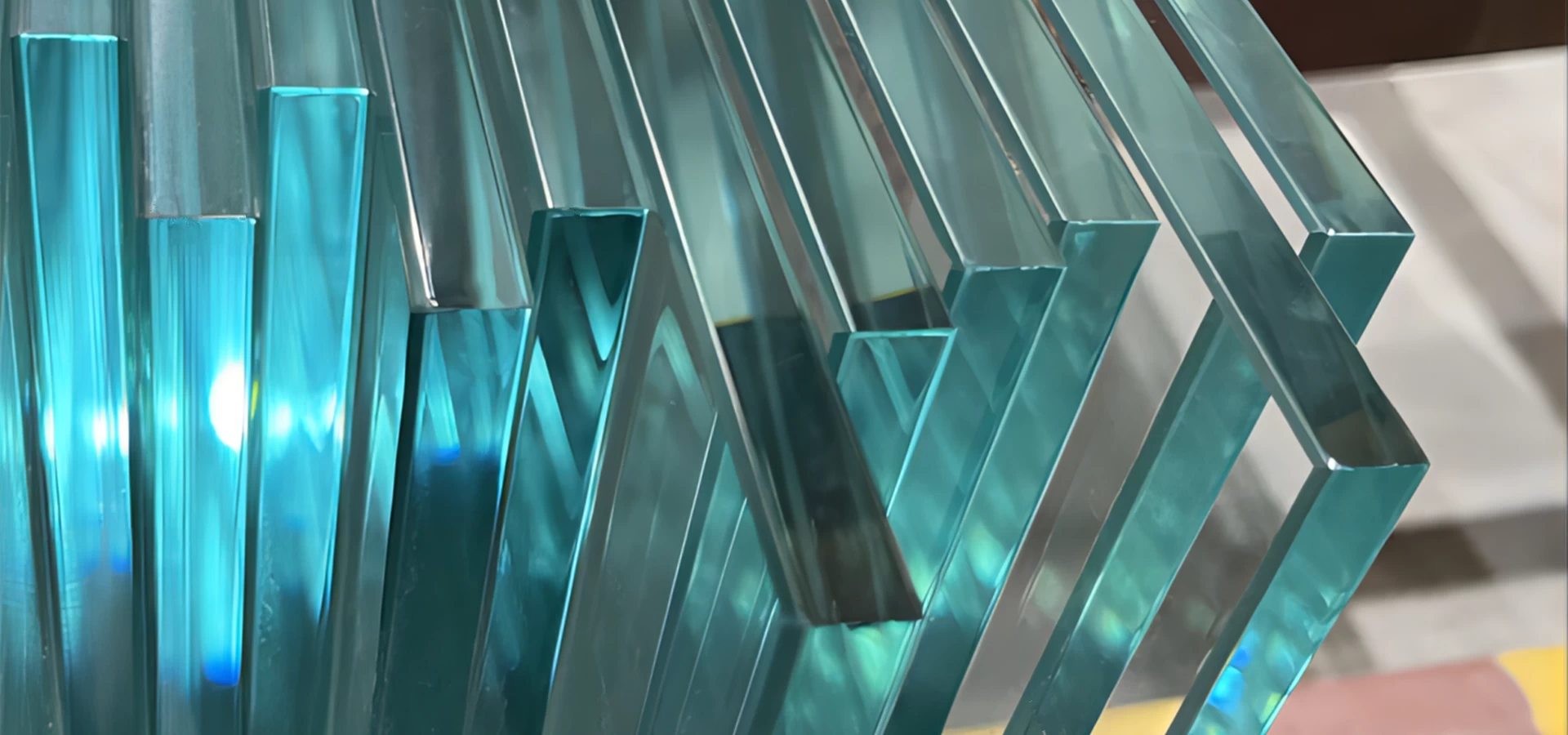

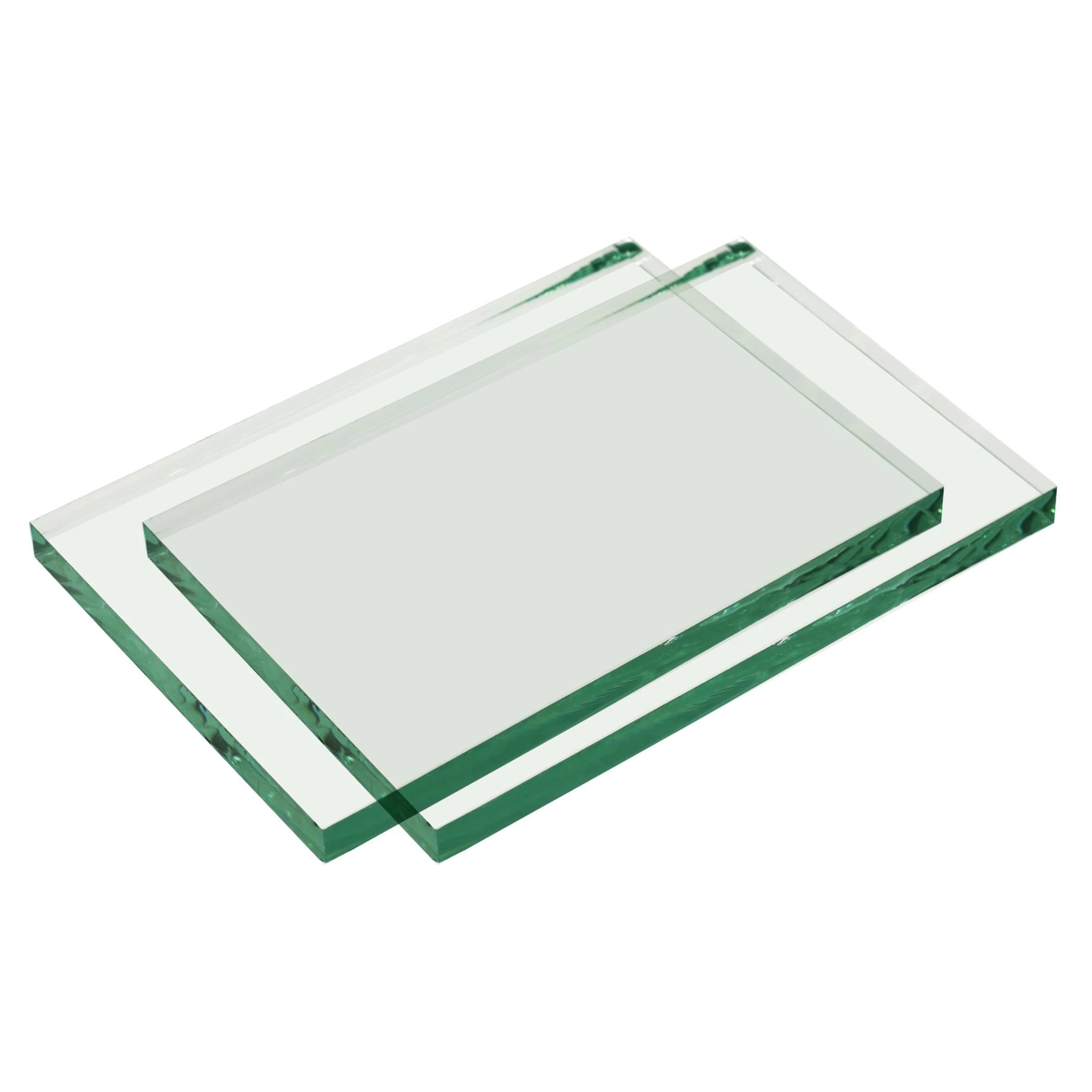

1.Glass cutting

Clear float glass, Ultra clear float glass, tinted glass, reflective glass, frosted glass, patterned glass…all could be used to make tempered glass. First cut them into a required size and shape.

1.Glass cutting

Clear float glass, Ultra clear float glass, tinted glass, reflective glass, frosted glass, patterned glass…all could be used to make tempered glass. First cut them into a required size and shape.

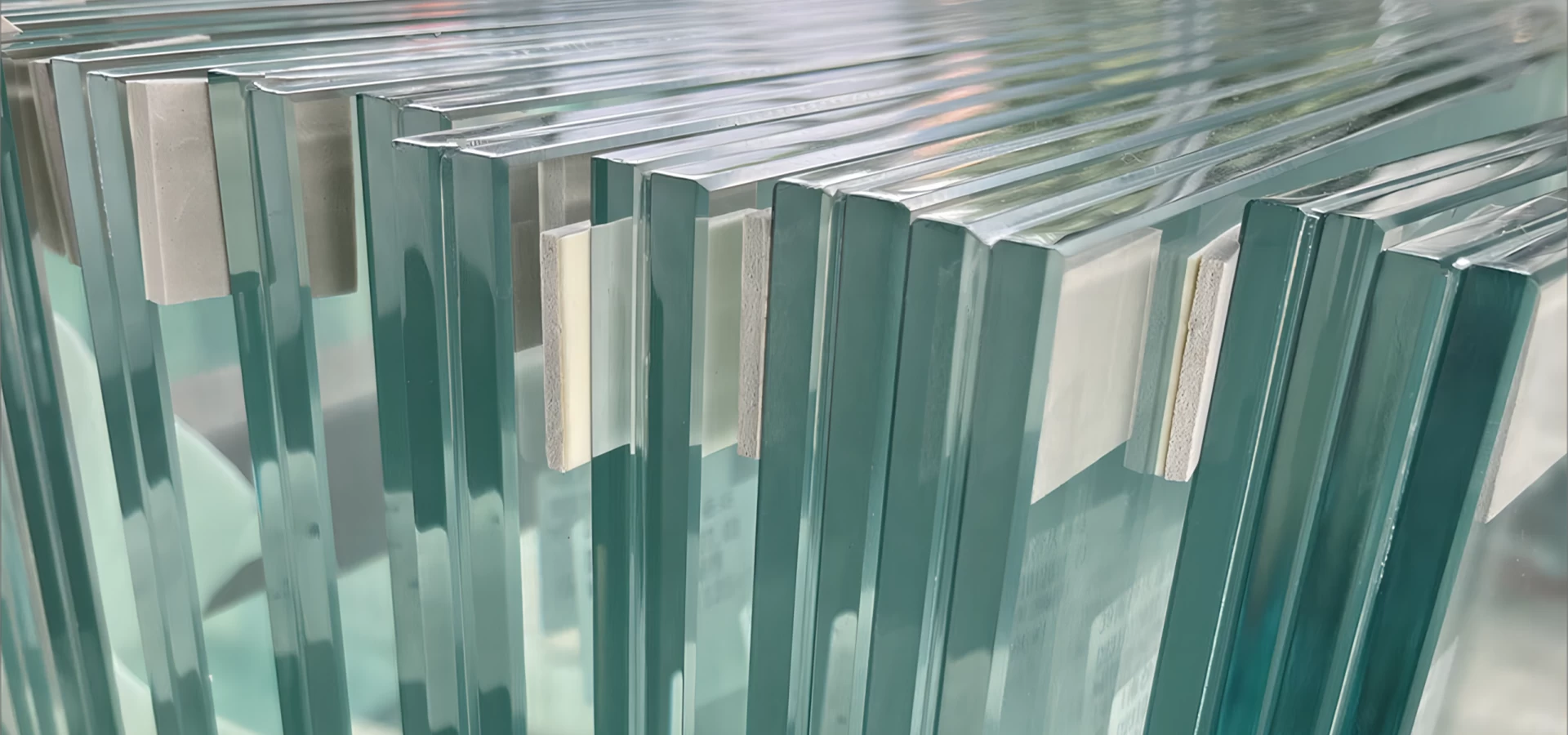

2.Drilling holes, Safety corner, Cutting Notches, Beveled edge, Polished edge

If the clients have any requirements about Drilling holes, Safety corner, Cutting Notches, Beveled edge, Polished edge, must do them before tempered. It will be better if the clients could provide the drawing, so we could know the details clear.

3.Inspect the glass and cleaning

Check if the glass have any scratches, stains, bubbles... under the led light. It it's okay, then transfer to clean and dry.

4.Tempered procedure

Transfer the glass to tempered furnace, heat to 700℃ around & make the glass reach softening point, then cooling suddenly. After tempered, the tempered glass’s strength is 5 times of ordinary glass.