How to prevent condensation for insulated glass

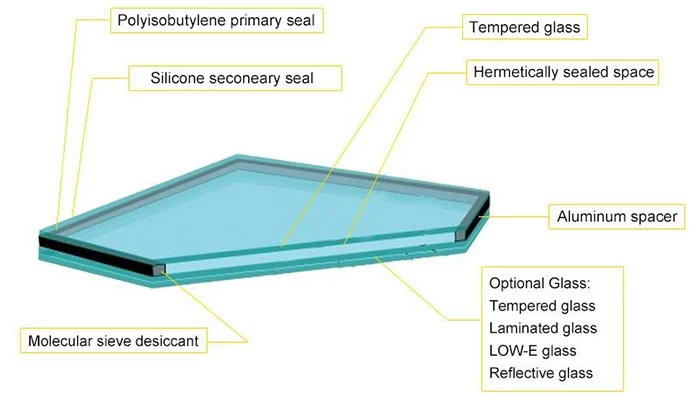

In the process of using insulated glass, when the environment temperature reduce to a certain degree point, it will make the surface temperature of glass reduced to the dew-point temperature in aluminum spacer, which lead to the surface of the dry aluminum spacer produce condensation or frosting and affect the properties of insulated glass. If the aluminum spacer can be guaranteed that will not produce condensation at temperatures below in minus 40 degrees Celsius, then the condensation will not appear in insulated glass.

Analysis of the reasons for the rise of dew-point temperature.

The dew-point temperature of insulated glass is the temperature at which the air humidity reaches saturation in the aluminum spacer. If it the temperature is lower than the dew-point temperature, the water vapor in the aluminum spacer will condenses into liquid water. Therefore, the higher of water content make the higher of air dew-point temperature. When the inner surface temperature of insulated glass is lower than the air dew-point temperature, the moisture in the aluminum spacer will become condensation or frosting on the inner surface of the glass.

The external moisture enters the aluminum spacer but not absorbed by the desiccant is the reason which make the dew-point temperature of insulated glass rise. There are three reasons that may lead to a rise in dew-point temperature.

1. There are bubbles in the sealant and cause air moisture enter in the aluminum spacer.

2. The water vapor enters the aluminum spacer through the diffusion of polymers.

3. The adsorption capacity of desiccant is too low .

Control measures for dew-point temperature.

1. Strictly control the temperature of the production environment.

2. Use low permeability coefficient sealant to make sure the reasonable sealing thickness and reducing the internal and external temperature difference of insulated glass.

3. Reduce the time of desiccant contact with the air.

4. Select the suitable aluminum profiles and desiccant.

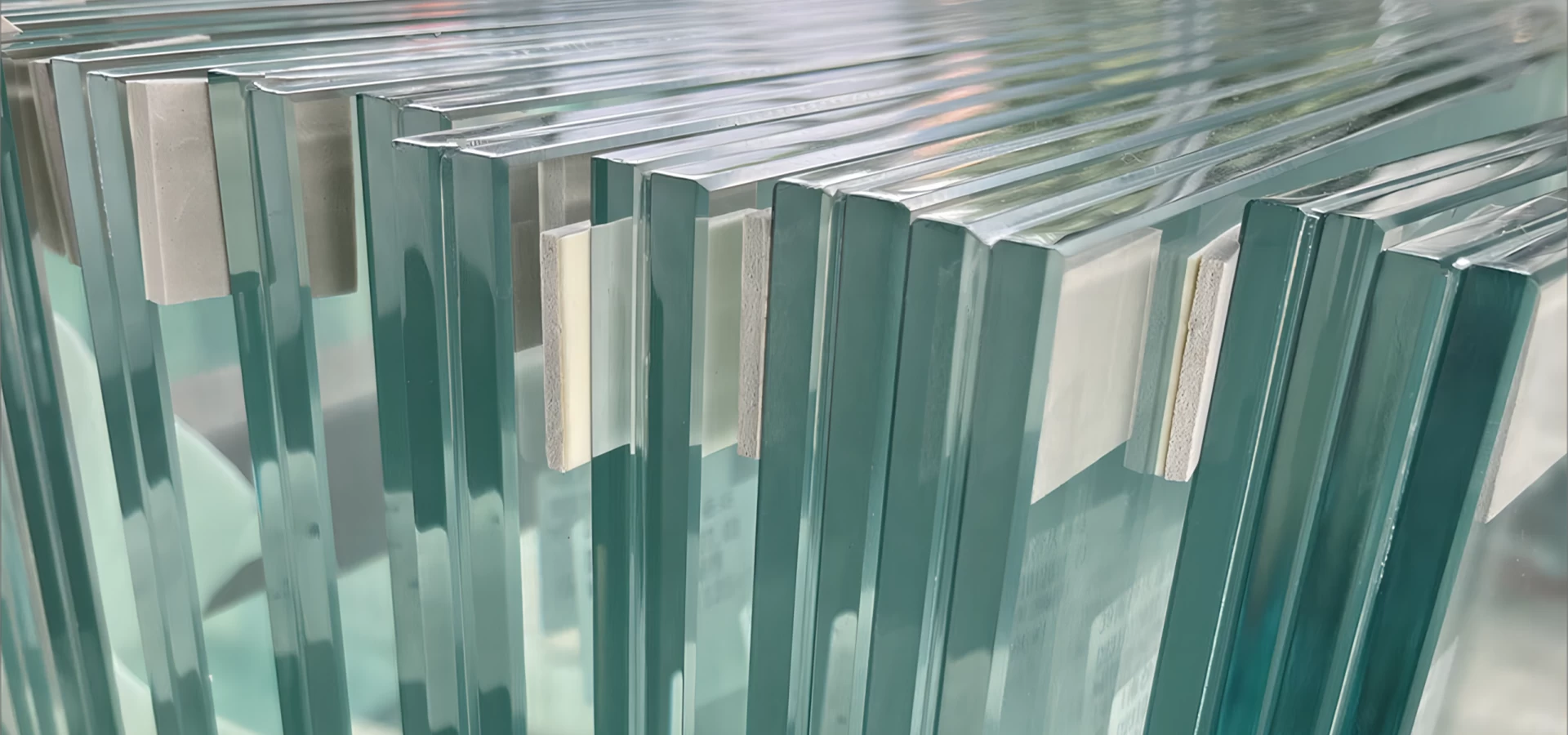

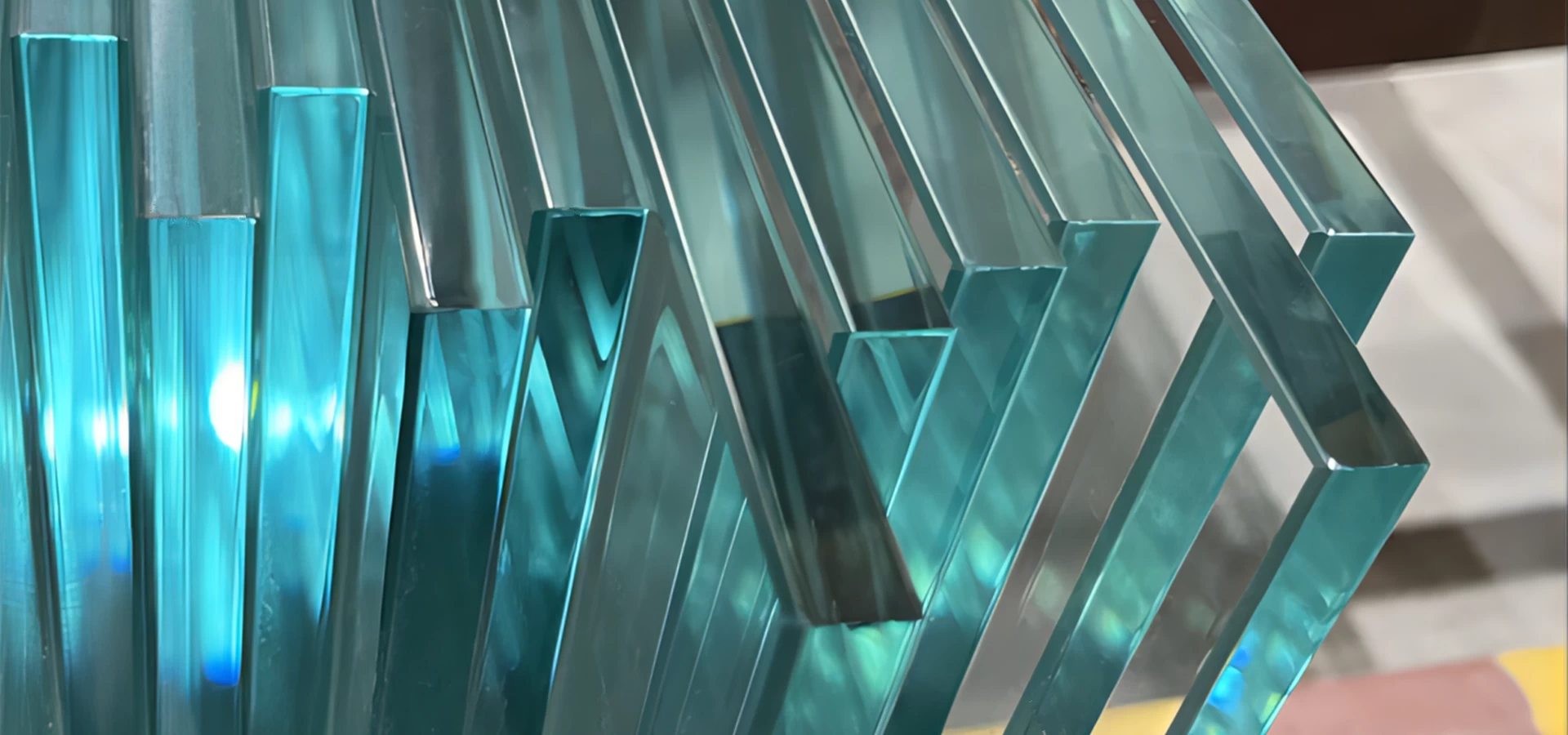

As a professional processed glass manufactured, Shenzhen Sun Global Glass has been accumulated a lot of experience in production of insulated glass, we produce high quality insulated glass by focus on all aspects, such as material selection, processing, and environment control etc.