How to Improve the Yield of Tempered Glass

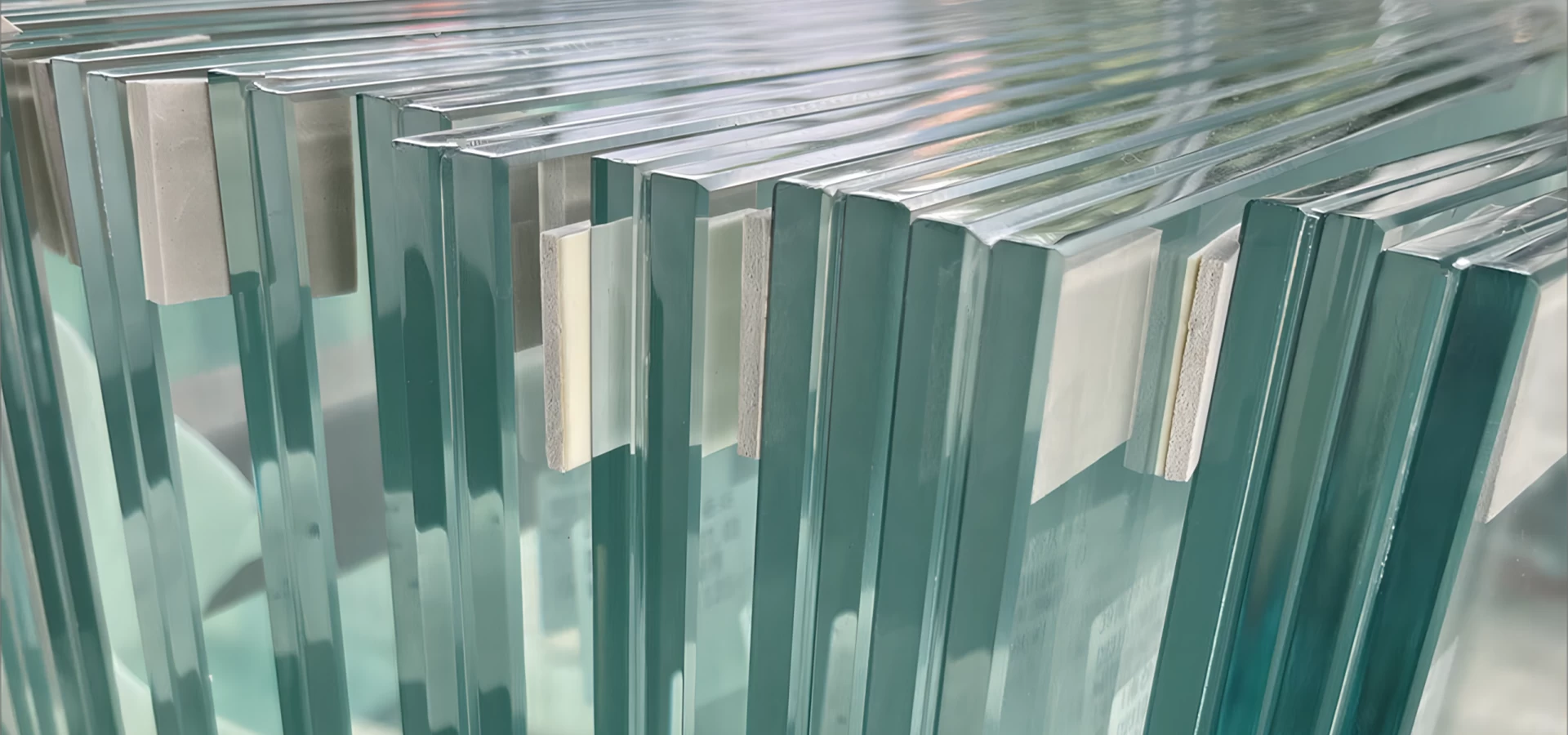

1.Float glass must bepolished before it is tempered.

The quality of polish plays a decisiverole in the yield of tempered glass. The edge will leave very small and fines cracks, even are hardly visible to the naked eyewhen the glass is being cut. There are two functions of polish, one is to make the glass look more beautiful and another is improve the yield of tempered glass.

2.Make sure the processparameters before tempered.

Process parameters is mainly include heating temperature, heating time, wind pressure time and cooling time. The tempered temperature is inversely proportional to the time of heating, heating time will more shorter when increase the temperature. However, when the thickness of the tempered glass is more than 12mm, it will easily burst in the furnace if the temperature is too high, even though there are many reasons cause to burst, but the high temperature is still the main cause. The most reasonable method is make the furnace temperature to around 665 degrees when the tempered glass ismore than 12mm and extend the heating time. Reasonable heating time should beset after determining the temperature, generally the heating time is about 40 seconds per millimeter. The heating time should be increased by 10% when the tempered glass is a large area, as well as holed glass. Dialectically mastering the heating time and heating temperature is very important, it is also the key to improve the yield of tempered glass.

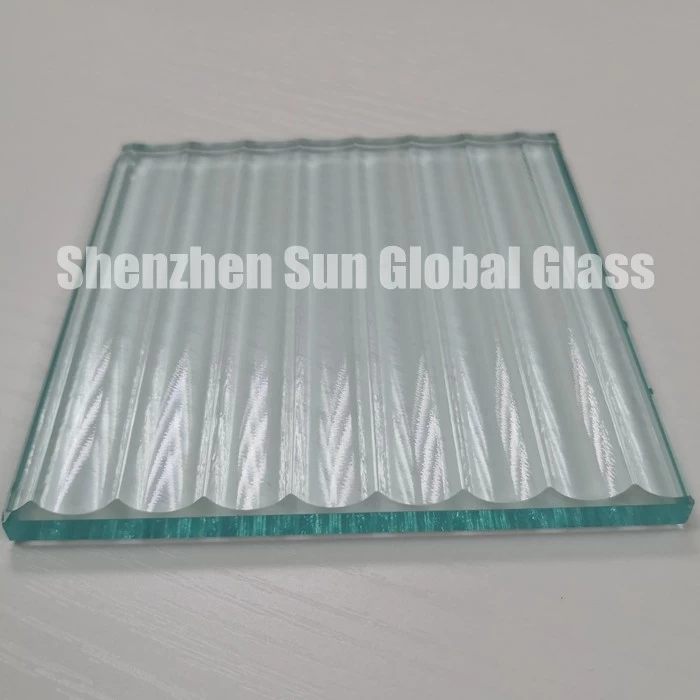

3.The importance of uniformheating of glass.

Actually, glass is a cube with 4 sides and 6 faces. The upper and lower sides of the glass is heated more slowly, especially for large area glass, when it is tempered, the middle part of the glass tends to be the slowest heat, sometimes the glass will appear apot shape after tempered, it is caused by the fast heating for edge and the middle part is heated slowly, which means after finish heating, the temperature at the edge of the glass is much higher than the middle part of the glass. If need large area glass heat homogeneity, the best way is to set the temperature of furnace to a heating curve, the temperature in the middle part should 10 degrees above the setting temperature while the temperature in the edge should 10 degrees below.

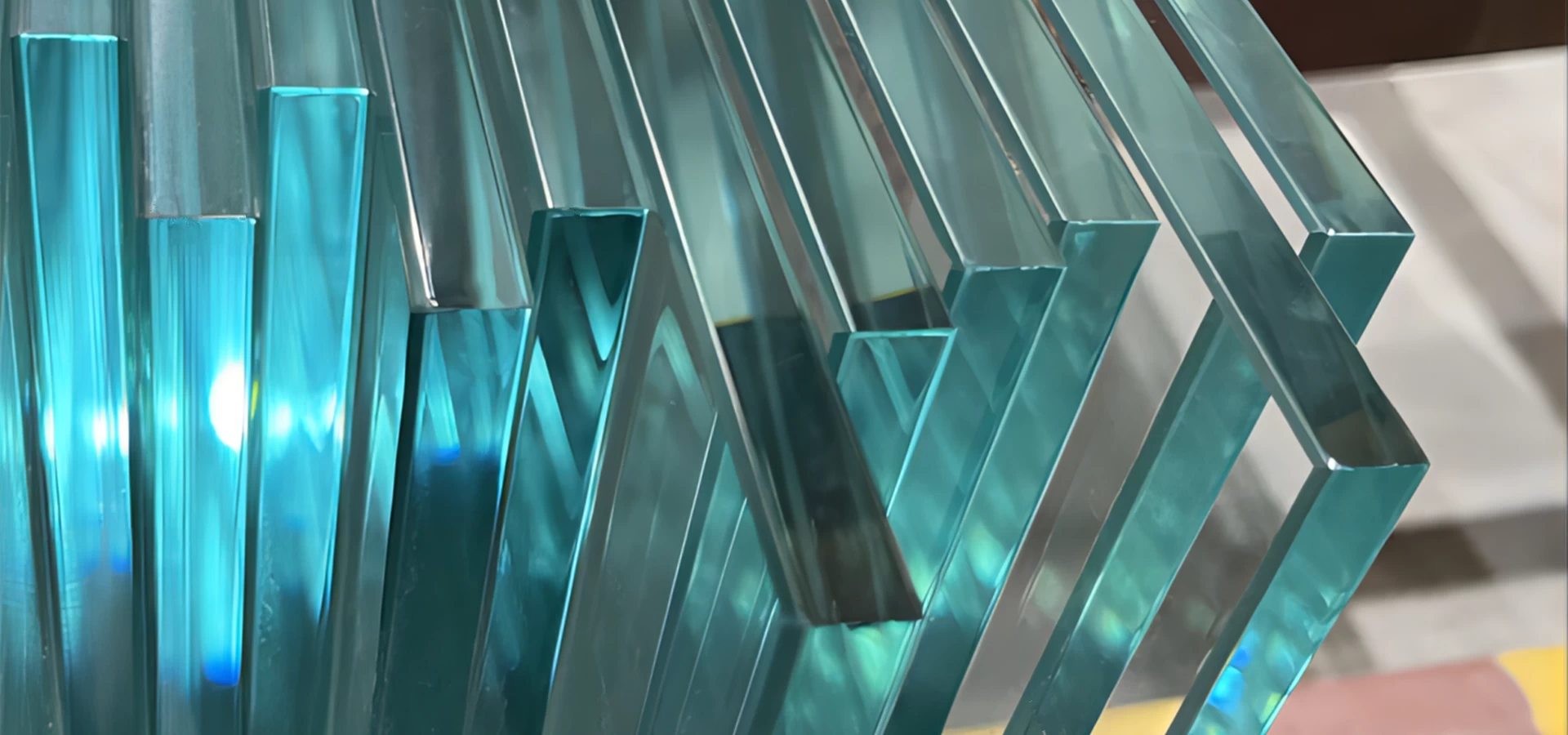

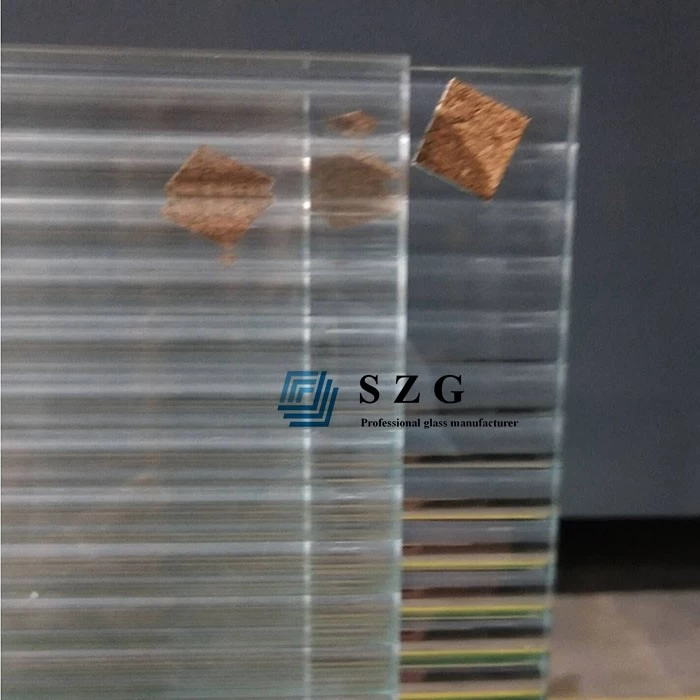

The yield of tempered glass is also reflects the quality of glass, Shenzhen Sun Global Glass equiped with innovative technicians and advanced production machines, only produce high quality tempered glass for each clients and provide 20 years warranty.