- Browse Categories

-

Tempered glass

- Laminated glass

- Insulated Glass

- Curved glass

- Decorative Glass

- Architectural glass

- Glass Window & Door

- Glass Shower Door

- Glass Railing

- Glass Partition & Wall

- Glass Floor

- Glass Skylight/Canopy/Roof

- Glass Facade

- Padel Court

- Staircase System

- Glass Dome

- Glass Greenhouse

- Glass Elevator

- Special glass applications

- Float Glass

- Clear float glass

- Low Iron Glass

- Tinted float glass

- Reflective glass

- Low-E glass

- Patterned Glass

- Mirror Glass

- Furniture glass

- Glass Fittings

- Aluminium Veneer

- Horticultural Products

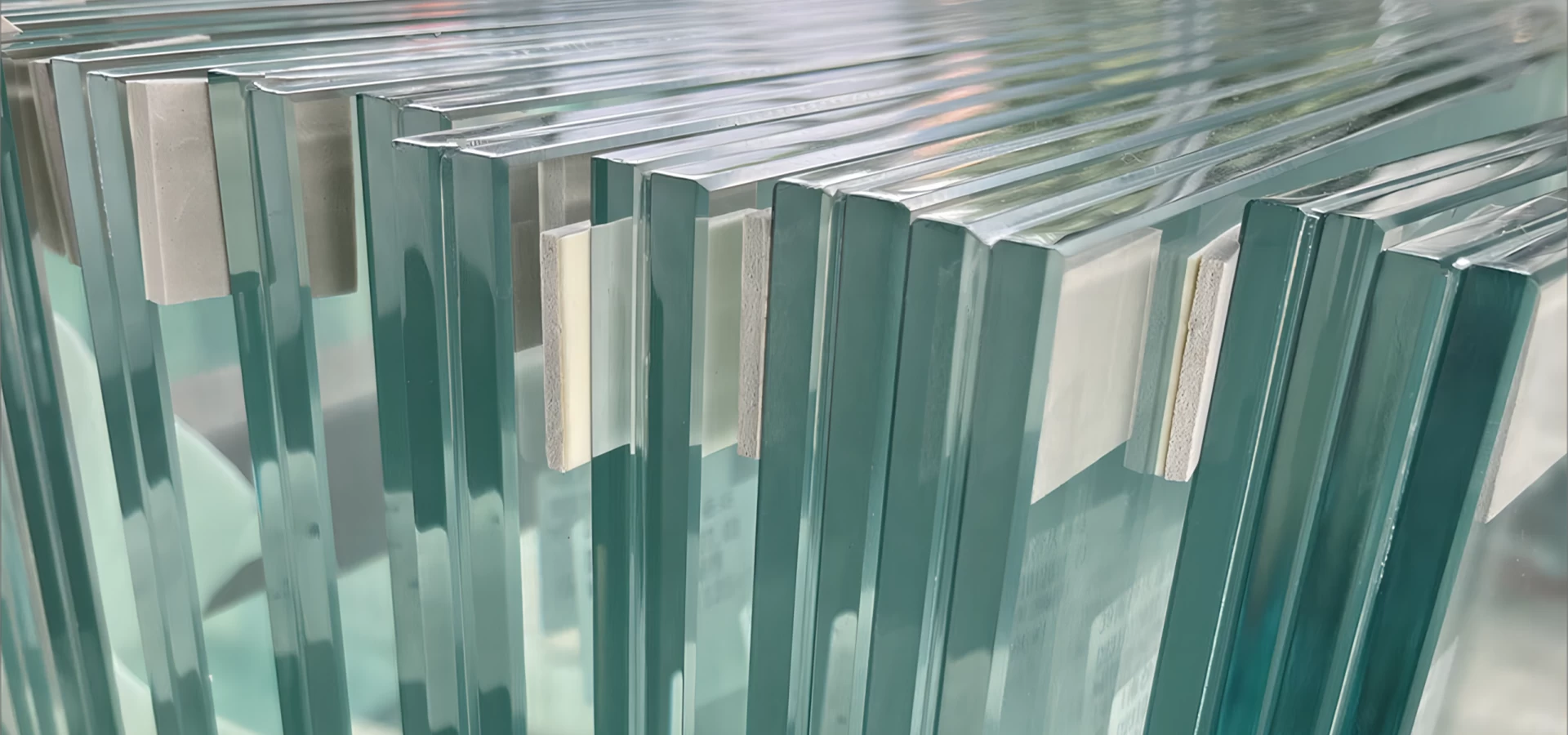

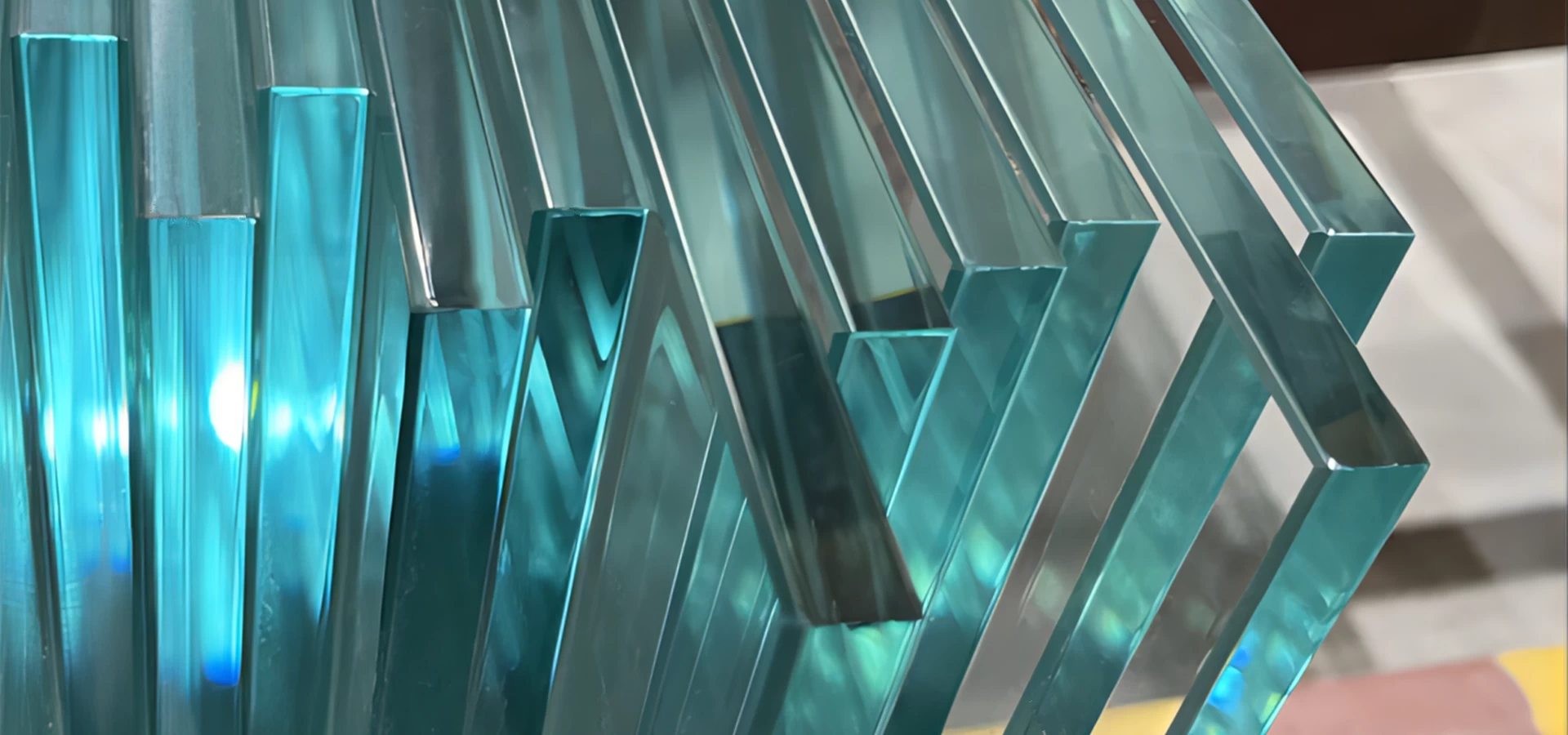

- Laminated glass

- Certifications

-

- Contact Us

- SHENZHEN SUN GLOBAL GLASS CO., LTD Address: 3F, QIHANG BUSINESS BUILDING, SHENFENG ROAD, LIUYUE, LONGGANG, SHENZHEN, GUANGDONG, CHINATel : 0086 755 84... Contact Now

- hot product

-

12mm fluted tempered glass, 1/2 inch low iron fluted toughened glass, 12mm fluted narrow reeded safety glass panel for interior decoration

CE standard complete padel tennis court glass price, full set portable paddle court tennis cost in China,Indoor and outdoor Padel Court construction systems for sale

broken glass table tops, shattered glass table tops, cracked glass table tops, 8mm 10mm 12mm 15mm tempered glass table tops

8mm ultra clear tempered fluted glass, toughened low iron decorated reeded glass, privacy interior glass for partition and bathroom

30mm tempered laminated glass floor manufacturer,10mm+10mm+10mm tempered laminated glass floor,30mm anti slip glass floor

12mm jumbo size clear tempered glass, 12mm jumbo size toughened safety glass,12mm tempered safety glass

10 mm clear tempered glass balustrade supplier, 10 mm toughened glass railings supplier, 3/8 inch tempered glass railings supplier

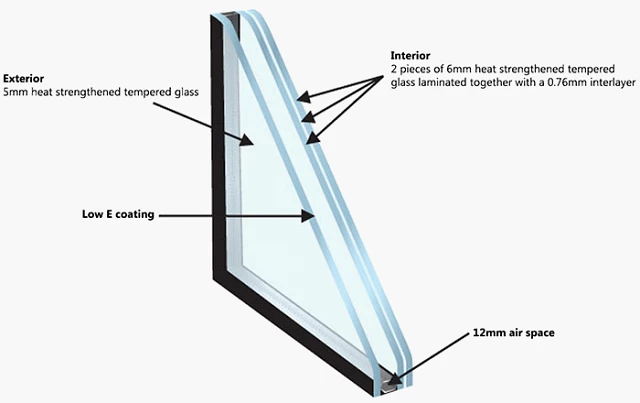

28.76mm low e laminated insulated glass, 10.76mm heat strengthened laminated glass+12mm air argon+6mm heat strengthened tempered glass, 28.76mm Double Glazing Unit

- Raw material: float glass

- Composition: 10.76mm heat strengthened laminated glass+12mm air argon+6mm heat strengthened glass

- Interlayer PVB thickness: 0.76mm

- Air argon thickness: 12mm

- Shape: Flat & Curved

- Size: max size is 3300mmx13000mm, custom size is welcome

- Package: strong new exportation wood crates

28.76mm low eheat strengthened laminated insulated glass (IGU) is consists of one piece of 10.76mm heat strengthened lamianted glass , one piece of 6mm heat strengthened tempered glass, and enclosed by a 12mm air spacer.

SZG laminated insulated glass offer an exceptional performance of reduce the heat gain or loss and allow for maximum design flexibility and creativity. By processing laminated glass into insulated glass, the safety of glass is increased, even when glass break, the fragments will adhere to the PVB interlayer, and minimizing the risk of injury and property damage.

For air space, we filled with argon and contain desiccant to remove moisture trapped in the gas space, thereby lowering the dew point of the gas in that space, and preventing condensation from forming when the outside glass pane temperature falls.

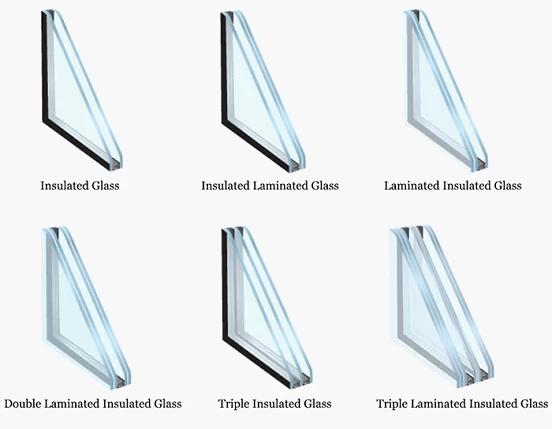

What Type ofInsulated Glass We Can Produce

Advantage of SZGLaminated Insulated Glass

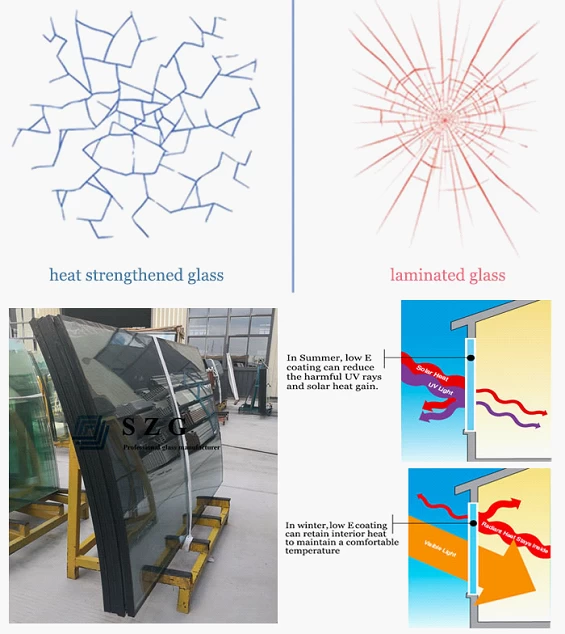

1. Safety performance: SZG 28.76mm laminated insulated glass is processed by heat strengthened glass and laminated glass.Heat strengthened glass and laminated glass are safety glass, heat strengthened glass is 2 times stronger than ordinary float glass and not spontaneous explosion. For laminated glass, SZG use the best quality PVB with feature of withstands penetration from impact, even if the glass break, the splinters will adhere to the PVB interlayer and not scatter.

2. Heat insulating and dissipating performance: the argon gas is much less reactive than air and don’t transfer energy as quickly, which means it can help the window keep the warm air inside. Low e coating is usually put on the inner sides of insulated glass to make sure it can never not be destroyed by the outside, low e serves a purpose both in the winter and summer time. The coating works by deflecting harmful UV rays to prevent overheating the room. The inner side low E coating can reflect warmth back into the house and reduce heat loss.

3. Flexibility performance: the laminated glass panel make the insulated glass has more flexible design, it can combinations of colored laminated and silk screen wired laminated glass etc. In addition,SZG provide customized service, we can custom glass structure according your inquiry and custom size for you, the max size we can do is 3300mmx13000mm, also, flat shape and curved shape are are welcome to custom.

SZG ProductionLine

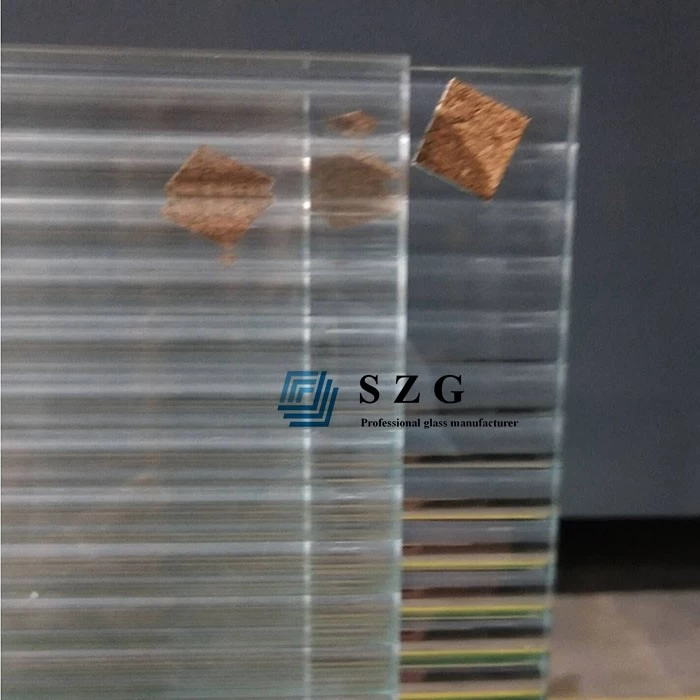

1. Process by using best quality clear float glass and PVB, each float glass sheet should be checked whether exist air bubble, stain , scratch and other defects.

2. Put the checked float glass into the tempering furnace, then produce heat strengthened through high temperature and quenching to make the surface layer less than 69MPa compressive stress and make the glass surface stress is around 24 ~ 69 Mpa.

3. Laminating processing must in non-dust room, then put the glass into the autoclave for 8 hours to ensure there is no air bubble between glass and PVB film.

4. Combination of two panes of glass with a layer of argon gas in between them, further separated two pieces of glass by an aluminium spacer bar, below the spacer bar material, a desiccant is used to absorb moisture and prevent the present in between the glass panes.

-12A-6mm-Low-E-heat-soaked-tested-Glass.jpg.webp)